Conveyor belt repair is an essential part of maintaining the conveyor system’s optimal performance. It involves repairing any damage or wear to the conveyor belt to ensure the normal operation of the conveyor system. Here are some key things you need to know about conveyor belt repair:

- Types of conveyor belt damage: The most common types of conveyor belt damage include cuts, gouges, punctures, tears, and belt edge damage. The cause of damage can vary from material handling, mechanical issues, and improper conveyor maintenance.

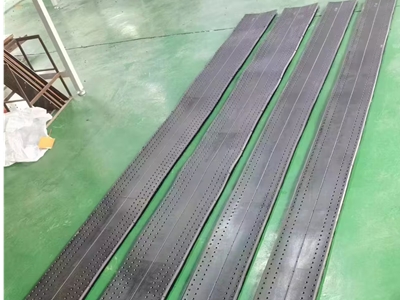

- Repair ways: Conveyor belt repair can be done through various methods, including vulcanization, cold repair, and mechanical fasteners. The repair method chosen depends on the type and extent of the damage and the belt’s material. Cold Repair is the most popular and widely used way, it is easy and convenient to operate, and the conveyor belt can be immediately used after repair.

- Importance of regular maintenance: regular maintenance is important to identify damage early and prevent more severe damage to the conveyor belt. Inspection, cleaning, and proper tensioning are crucial maintenance works.

- Safety considerations: Conveyor belt repair can be dangerous, and safety should be a top priority. Proper safety rules should be followed, including lockout/tag-out procedures, using personal protective equipment (PPE), and ensuring proper training for repair operators.

- Quality of repairs: High-quality repairs are critical to ensuring the conveyor system’s excellent performance and reducing downtime. Repairs should be done by experienced professionals using quality materials and techniques to ensure the repaired belt’s long service life. Today, we will see here what Beltcare Solution could do, they supply reliable conveyor belt repair materials such as rubber repair strips, diamond repair patches, Filler Rubber, cold adhesive cement, etc, furthermore, overseas on-site service can be supplied as customers required.

Overall, conveyor belt repair is important to maintain a conveyor system’s performance and safety. Regular maintenance, safety considerations, and high-quality repairs are all essential components of a successful conveyor belt repair construction.