Conveyor Belt Repair Tape – Definitive Guide

During the bulk material conveying of the belt, various damages may occur due to material dumping and fall. Such as longitudinal tearing, edge damage, gouges, deep punctured, and so on. For these questions, we need to evaluate whether the conveyor belt is repaired or replaced.

If the conveyor belt cover rubber wear is near the limit, the tear is more than 7 points per meter length, the horizontal puncture reaches 1/3 of the belt width, it needs to replace the damaged part with a new belt. However, most of the damages can be repaired by cold vulcanization solution.

What is Conveyor Belt Repair Tape

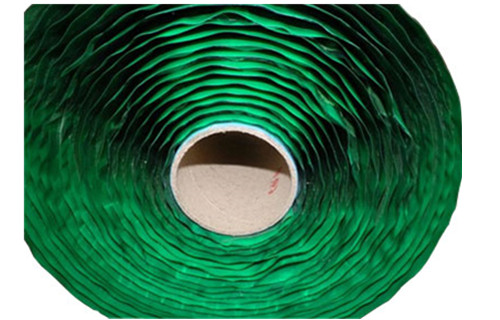

Conveyor belt repair tape is often called conveyor belt repair strip or rubber repair strip, or rubber repair patch, it is made of synthetic rubber, which compounds with superior quality semi-vulcanized bonding layer on one side. Conveyor belt repair tape is highly wear-resistant, and natural rubber strips designed to repair the damage to conveyor belt covers.

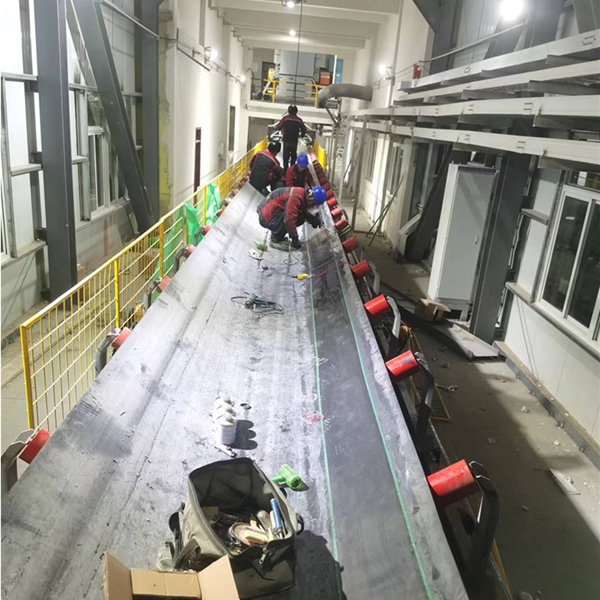

As Conveyor belts are often exposed to heavy stress, this leads to wear and tear on the belt, surface damage, or even holes, repair such damage with our conveyor belt repair tape for cold vulcanizing fast and efficiently. Furthermore, it can be used to repair longitudinal breaches, damaged topcoats, damaged edges of the belt, or bonding rubber to steel surfaces too.

Conveyor Belt Repair Tape Features

Cold Bond Repair is easy to operate and fast install, with a rapid cure time allowing for normal use of the conveyor belt in as little as one hour.

Beltcare solution Conveyor Repair repair tapes have characteristics of high tensile strength and abrasion resistance, and each product is supplied with a CN bonding layer, together With REMA/TRS cold vulcanized cement, this will achieve ultimate adhesion when bonded to rubber conveyor belt surfaces.

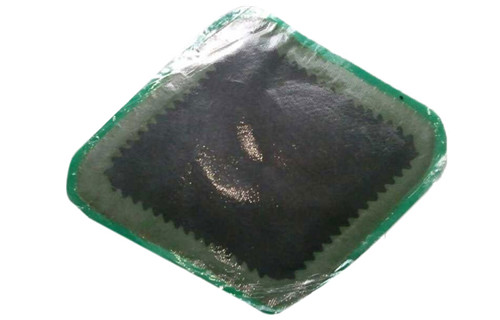

BELTCARE solution Conveyor Belt Repair Tapes or Patches are supplied with a feathered edge to allow the repair strip or patch to merge with the existing conveyor belt cover completely.

Types of Conveyor Belt Repair Tape

The conveyor belt repair tapes are available in standard and reinforced types. The conveyor belt repair tapes of different sizes are selected to repair according to the actual damage size. Generally, it is better that the conveyor belt repair tapes are 20-30 mm wider than the belt damaged part and repaired by internal embedding.

Fabric reinforced repair tapes thick is about approximately 1.4 mm more than the standard type, they are recommended to use for the repair of damage to conveyor belt ply and covers or steel cord conveyors in heavy operating conditions or applications, which require maximum tear strength and puncture resistance.

How do you fix a ripped conveyor belt?

Your operating steps will directly affect the repair effect, please do it strictly according to the following steps:

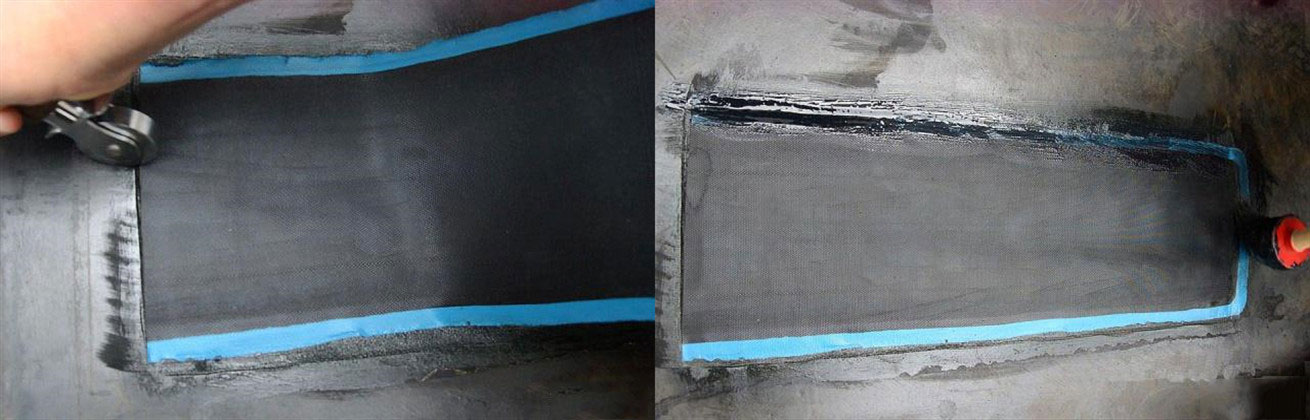

- Grinding and Cleaning

You should calculate the grinding area first, the grinding width and thickness should conform with the rubber repair strip. Then use the Angle grinder and tungsten steel polishing plate to polish the damaged surface. Finally, sweep away the residue, clean it with a cleaning agent, and dry it.

- Mix and Glue

After mixing the cold curing adhesive and curing agent in proportion, evenly brush the mixture on the adhesive surface, wait some minutes, and test it with the back of your hand. a moment later, brush it again. The CN layer(bonding layer) of the rubber repair strip also needs to brush a layer of mixture.

- Bonding and curing

If you feel slightly sticky when touching the surface again, it’s time to bond it. Please paste the patch strips from one side and use a compacting roller to compact them from the middle to the sides, it can drain the air. Finally, brush the joint evenly on the surface with the mixture.

Everything is ok, then wait 2 hours for its natural vulcanization. At this step, you can use the conveyor belt for your projects. It is fast and easy to operate, and doesn’t need to stop all the conveyor system

How to Choose Conveyor Belt Repair Tape?

A conveyor belt repair tape can be used for repairing local damage, long-distance belt scratches, and sealing between the cold adhesive head portion. It is generally divided into two types, standard conveyor belt repair tapes, and reinforced conveyor belt repair tapes.

Conveyor Belt Repair Tape Specifications

Different common specifications are available in the conveyor belt repair tapes: 100mm\150mm\220mm\300mm\400mm. We need to choose the appropriate rubber repair tape according to the actual situation of the conveyor belt.

The front side of the conveyor belt repair tape is made of wear-resistant rubber, and the back side is a semi-vulcanized CN layer, which forms a cold vulcanization reaction with the cold vulcanization adhesive to strengthen the bonding strength of the damaged surface of the belt.

We take the commonly used conveyor belt repair tape as an example to introduce it in detail.

Reinforced Repair Tape

Compared with standard conveyor belt repair tapes, reinforced conveyor belt repair tape contains a high-strength fabric inside, this type of rubber repair tape has a superior breaking force, which is suitable for the longitudinal tearing repair of the conveyor belt and the repair of structural damage

See the authoritative technical data as follows: Fabric Layer Lateral Tearing Force(N/mm):89.5; Fabric Layer Longitudinal Tearing force(N/mm):218

Anyhow, both the standard rubber repair tape and the reinforced rubber repair tape are definitely excellent conveyor repair materials for conveyor belt damage.

Standard Repair Tape

It is made of a synthetic rubber compound with superior quality semi-vulcanized bonding layer on one side. It is highly elastic, high wear-resistant, leakproof,cutting-resistance, waterproof, and flame retardant. the standard conveyor belt repair tape is suitable for the long distance scratch of the conveyor belt.

Furthermore, the standard rubber repair tape has a good fit and outstanding flexibility, it can be used to treat the sealing between belt cold joint sealing face and non-face.

Importantly, our conveyor belt repair tapes have the authentic CN layer(bonding layer), they don’t need to polish before use and can be bonded directly. And the bonding layer adhesive Force increases with time, while the adhesion of the inferior bonding layer doesn’t change over time, it is another characteristic of the authentic CN layer.

Conveyor Belt Repair Tape Sizes Selection

The width of the conveyor belt repair tape is mostly used in the three specifications, 100mm, 150mm, and 220mm. Here are the common specifications of conveyor belt repair tapes as following:

The specifications of standard repair tapes (without fabric reinforcement) (thickness * width * length) are as follows:

2.2*100*10000mm; 3.2*150*10000mm; 3.2*220*10000mm; 3.4*300*10000, mm; 3.4*400*10000mm

Reinforced repair tapes (with fabric reinforced layer) (thickness * width * length) specifications are as follows:

3.6*100*10000mm; 4.6*150*10000mm; 4.6*220*10000mm; 4.8*300*10000mm; 4.8*400*10000mm

Usually, the rubber repair tape width is 20-30mm wider than the edge of the damaged part of the belt. it could make the rubber repair tape merge with the conveyor belt well in patching.

For the convenience of customers, various sizes of conveyor belt repair tapes are available, such as the following widths: 50mm, 75mm,100mm,150mm,220mm,300mm,400mm,500mm, etc, all sizes&shapes can be customized.

And we supply a full range of conveyor belt repair materials including Conveyor Belt Repair tapes, Rectangular Repair Patches, Diamond Repair Patches, CN Filler Rubber, EP Repair Fabric, and so on

In order to better serve the customers, Maintenance&Installation guidance will be supplied as required, and overseas On-Site construction & maintenance service can be provided upon request

You can also check here to know the maintenance operation how to use the conveyor belt repair strip?