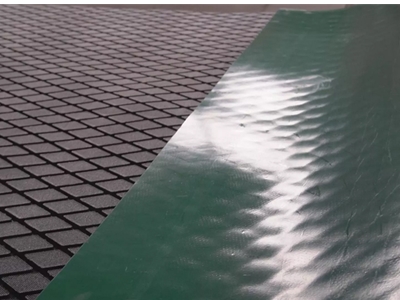

Diamond Strip Lagging is designed for use as lagging of conveyor belt pulleys to increase grip, and reduce wear and corrosion of the pulley shell. It could prevent any type of belt slip, increase the productivity life of your conveyor pulley

Diamond Strip Lagging

Description

Diamond Strip Pulley Lagging is a diamond pattern strip lagging with a neoprene based bonding layer, it is manufactured in a strip form, 200mm width. It is ready for easy application without removing the pulley if required. Rubber Pulley Lagging Strip is well-matched with slide lagging to use on conveyor pulleys of conveyor systems.

Rubber Strip Pulley Lagging has excellent resistance to wet and dry abrasion and will flex against the conveyor belt, It could increase the protection of pulley shell from wear leading to early failure.

Feature

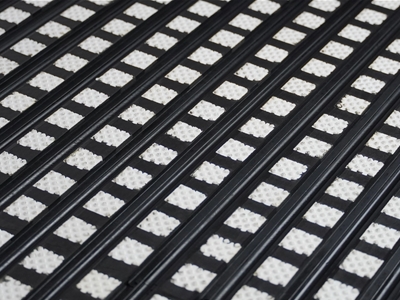

1. Increase coefficient of friction between conveyor belt and pulleys surface, extend pulley life and increase productivity.

2. Supplied in strip of 200mm width is easy to install, it can be done in place, on plant site or at pulley manufacturer

3. Specially formulated combination of NR,SBR etc rubber compound and neoprene bonding layer provides our pulley lagging with excellent gripping strength and wear resistance

4. FRAS rubber compound make it can be used in above or underground applications