Multiple Conveyor Rubber Pulley Lagging For Your Choose

We supply plain& diamond rubber pulley lagging and Ceramic Pulley Lagging with superior quality rubber compound, all our pulley laggings are proven to eliminate belt slippage, increase pulley life, improve water shedding and boost productivity, they are better used to protect the drum&belt.

Conveyor Pulley Lagging- Definitive Guide

Conveyor pulley lagging is essential to improve conveyor belt performance, the combination of our pulley lagging can reduce belt slippage, improve tracking, and extends the life of the belt, bearing & other components.

What is Pulley Lagging

The Drum is the power source for the conveyor system, it is gradually oxidized in harsh working conditions and some chemicals will chemically corrode it too. Therefore, it is necessary to cover with corrosion-resistant & aging resistance pulley lagging to protect the drum.

In a word, pulley lagging is the layer of material, which is sticks to the conveyor pulley shell. It can protect the pully shell from damage, increase friction with the conveyor belt and dispense water off the pulley.

Why Need Pulley Lagging?

For the conveyor systems, they often have to perform in the most difficult conditions, such as rain and sludge, which cause slippage between the conveyor belt and pulleys because of the friction coefficient between the two parts. Such damages are not only expensive to repair but also time-consuming and cause enormous losses due to downtime. The conveyor belt needs good traction with the driver pulley to prevent slips that can cause major damage.

By installing a pulley lagging between the pully surface and the belt, it can make the belt run without slipping, which could extend the service life of the both conveyor belt and the pully.

Pulley Lagging Types

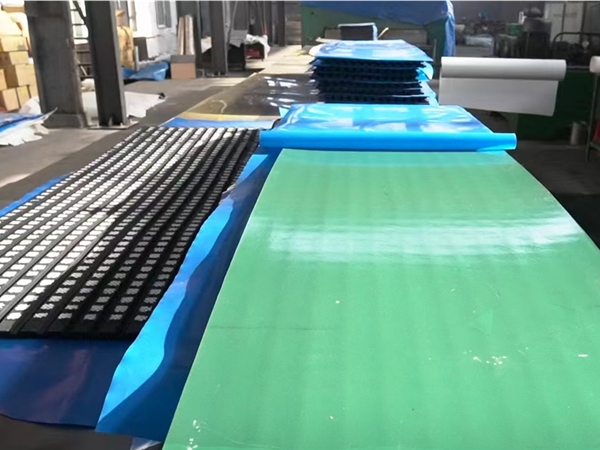

Cold vulcanized pulley lagging is generally divided into Ceramic Pulley Lagging, Diamond Rubber Pulley Lagging, and Plain Rubber Lagging. All pully lagging has the advantages: on-site installation, easy to operate; high efficiency and save cost.

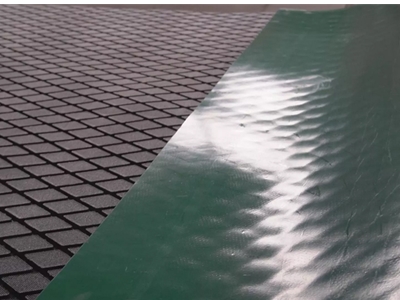

Diamond Rubber Lagging has a superior Abrasion Resistant which can extend rubber life and ensure conveyor system productivity. It increases the coefficient of friction between the drive pulley and conveyor belt, increasing grip and reducing slippage, improving drive and tracking of the conveyor belt.

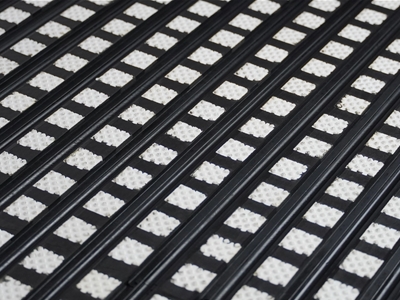

Ceramic Pulley Lagging generally has 40% ceramic tiles coverage(The other ceramic coverage of 15%,59%, and 100% are available as custom request), it increases the coefficient of friction and maximizes grip. The ceramic tiles grooves are for shedding dirt and water away from the pulley to obtain a self-cleaning function.

The plain lagging can be used to eliminate belt spillage, water-shedding, and increase pulleys’ service life. Furthermore, we also provide the lagging filler is made of 200/220mm diamond lagging strip.

Pulley Lagging Application

The Rubber & Ceramic Pulley Lagging is mainly used for conveyor system applications in the mining, quarrying, and mineral and metals processing industries but can be used on conveyor pulleys in any application where required.

The Plain Rubber lagging is mainly suitable for the drive drum of the medium and high tension conveyor belt applications and the diamond pulley lagging is mainly suitable for drums of the fabric belt and the medium and low-strength steel belt. The Ceramic pulley lagging is best suited for use in wet and dirty conditions and high tension belt applications.

Pulley Lagging Procedure

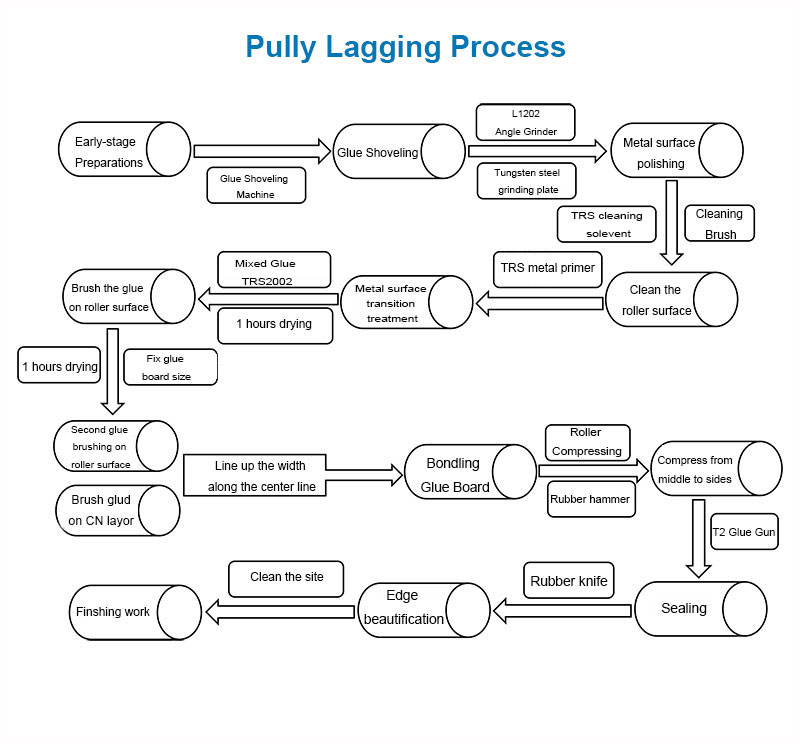

Disconnect the power supply and hang the safety warning board.

We shovel glue according to the status of residual glue on the roller surface. If the residual glue exceeds 0.5m, a shoveling glue machine must be used to remove the residual glue.

Before shoveling the glue, the roller must be rotated by humans. If it cannot be rotated, the connecting pin between the roller and the reducer must be removed. If the residual adhesive area is less than 0.5m, then there is no need to shovel the adhesive.

Note: When shoveling the glue, the angle between the flat chisel and roller surface should be 15-30 degrees, or it will shovel off the steel body, damage the flat chisel.

Polishing

There are many dirt, dust, grease, water, rust, and other organic or inorganic contaminants on the surface of the metal, which affect the wetting of the glue.

In order to improve the bonding strength, it is necessary to adopt mechanical, physical, chemical, and other methods to rough, clean, activate the surface of the adhesive, change the surface properties.

It can facilitate glue infiltration, make the glue has a firm binding, and finally improve the durability and service life of the bonding.

After the surface treatment, the metal surface can be changed into a kind of adhesive surface with high activity and high effective area.

There are two ways that can solve the problem, mechanical grinding and sandblasting. They can provide the surface with appropriate roughness, increase the effective bonding area, improve the glue to the surface of the adhesive infiltration, and the adhesion performance.

For the metal surface treatment of the roller, we usually use a steel brush or grinding machine to brush the loose oxide layer.

At present, the angle grinder with a tungsten steel grinding plate to do the grinding treatment, not only can improve the grinding efficiency but also can prevent the aging phenomenon on the surface of the roller.

Cleaning

After polishing the surface, there is a lot of dirt, dust, grease, water, rust, and other organic or inorganic pollutants, which affecting the glue adhesive effect.

We should use a cleaning agent to clean the surface. The cleaning agent should have a good quality, which can protect the metal surface from corrosion.

You can clean it several times to make sure the surface is totally clean. After the cleaning, dry it for some time, it can guarantee a good adhesive effect for glue.

Transition

Brush a layer of metal primer evenly on the metal surface. Waiting an hour to let it dry completely.

The metal primer can not only prevent surface pollution but also prolong the storage life of the treated metal. It’s a great way to guarantee the wetting performance of the adhesive, and increase its adhesive strength and durability.

Gumming

Evenly brush the prepared cold vulcanized glue on the metal surface, and let it dry completely. The drying time is about 15-45 minutes.

Brush the second layer of cold vulcanized glue after the first glue dries completely. After the second glue can slightly stick to the hand, you can do the final surface bonding.

The bonding surface of the common glue board should be polished and cleaned first, then brush the glue twice. The RIT glue board only needs to brush once, and there is no need to polish and clean.

Bonding

You should fix the bonding reference line on the roller surface first. After the second glue brushing, it’s easy to find the reference line for the bonding board.

Here is the line drawing method:

- Take the two sides of the roller as the reference, and draw the reference line with a square, steel ruler, and knife.

- Cover the semi-vulcanized layer of the glue sheet with a clean plastic film.

- Using the reference line found on the roller as a reference, tear the plastic film about 50mm wide and start to paste the rubber sheet on the surface of the roller.

- After confirming the correct position, start to tear off the plastic film. While tearing it off, wipe it down with your hands. Note: Don’t tear it too much, or it will be very firm after being glued and cannot be torn off

- If the sticking is skewed and the sticking area is not large, you can drop the cleaning agent between the rubber sheet and the steel body of the roller and slowly tear it off. Then brush cold vulcanized glue to the area where the rubber sheet and the roller are pasted, and then paste it after it dries slightly.

Sealing

Use a knife to cut out the V-shaped opening at the seam of the rubber sheet. The width of the outer opening is 15mm. Polish the V-shaped opening with a steel wire polishing brush, then brush off the rubber powder.

Next, you should brush the T2 adhesive to the V-shaped opening twice. Then use the T2 glue gun to fill the T2 glue, at the same time, keep pressing down with a compacting roller.

Trimming

Use a rubber knife to cut off the excess rubber at the edge of the roller. Keep the angle of the rubber knife at an angle of 45° with the surface. While rotating the roller, remove the excess rubber.

Conclusion

Conveyor pulley lagging is essential to improve conveyor belt performance, the combination of our pulley lagging can reduce belt slippage, improve tracking, and extends the life of the belt, bearing & other components.

We supplied both plain and diamond patterned pulley lagging with specially developed rubber compound and their plain & patterned surface proved to eliminate belt slippage, increase pulley life, improve water shedding and boost productivity.

And a premium level of Ceramic Pulley Lagging is offered to be better used to extend the conveyor life, reduce wear, prevent belt slippage and create a self-cleaning action.

As an authentic CN layer(Bonding Layer), all our Ceramic Pulley Lagging, Conveyor Rubber Pulley Lagging CN layers don’t need to be sanded, they can be bonded directly.