Ceramic Pulley Lagging

Ceramic Pulley Lagging – Definitive Guide

In the following guide, you will know everything about Ceramic Pulley Lagging.

Ceramic Pulley Lagging – Definitive Guide

The ceramic pulley lagging has a longer service life due to its durability and reduced lagging wear. The amount of ceramic coverage on the surface of the backplane can be customized according to the application. The amount of ceramic cover can also increase or decrease the level of friction and grip.

[lwptoc skipHeadingLevel=”h1″ skipHeadingText=”*Beltcare Solution- Ceramic Pulley Lagging Supplier|*Project|*Factory|*Ceramic Pulley Lagging FAQ|*Are you a trader or manufacturer?|*Can I get samples to test? How does it charge?|*What is your return policy?|*What’s the lead time after we placed the official PO?|*Can you use our company logo or label?|*Which kind of certificate do you have?|*Ceramic Pulley Lagging – Definitive Guide|*Send Your Inquiry Today!”]

What is Ceramic Pulley Lagging?

The design of ceramic pulley lagging is suitable for conveyor belt drive pulleys running under extreme conditions. It is suitable for wet and dirty conditions and high belt tension applications. It can also be used in environments with dust, icing, or steep slopes

Ceramic pulley lagging is a high-quality pulley lagging material, ceramic tiles are molded into rubber compounds. This allows excellent traction, eliminates slippage, and provides excellent wear resistance. Ceramic pulley lagging is especially suitable for the problems of slippage and excessive wear, which makes ordinary rubber pulleys ineffective. It is widely used in driving pulleys, and buffer wheels, curved wheels, and tail wheels.

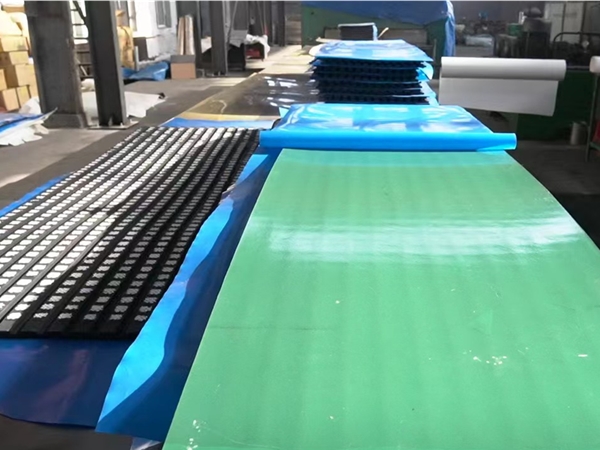

Types of Ceramic Pulley Lagging

Generally, ceramic pulley lagging can be divided into two common types, dimple and plain ceramic tiles surface. These two types of ceramic lagging significantly increase friction and grip and can reduce belt slippage.

The dimple ceramic pulley leggings are usually lagged in the drive pulley because it increases friction and grip to assist in driving the conveyor belt. Non-driven pulleys can use smooth ceramic; however, this is not common.

plain ceramic pulley lagging is often used for non-driven pulleys because the required friction is significantly reduced and unnecessary friction can cause additional belt wear. The use dimple ceramic pulley lagging on non-driven pulleys is likely to cause scratches and wear on the belt when unnecessary friction and slippage occur.

Besides, it is available for the following types according to the different ceramic tiles coverage:

45% Ceramic Tiles Coverage.

It is the common type for general purposes, she provides the solution when conventional rubber fails to correct belt slippage and wear problems. It is the popular and widely used type.

59% Ceramic Tiles Coverage

Anti-Slipping Purpose. It features high friction and is suitable for drums with slippage and excessive wear&tear problems which make common rubber Beltcare ineffective.

100% Ceramic Tiles Coverage

It features superior long service life and is mainly used on non-drive pulley due to the smooth & solid ceramic surface

15% Ceramic Tiles Coverage

Economic Purpose. It is cheap and mainly used on the head drums as well as bend or tail drums.

Ceramic Pulley Lagging Features and Benefits

The ceramic pulley lagging has a longer service life due to its durability and reduced lagging wear. in general, our ceramic pulley lagging service life can be up to 10 years, and the wear resistance is 8-10 times of the common rubber pulley lagging sheet.

Reduced Belt Slippage

High wear-resistant and 45% coverage ceramic surface, the 95% AL2O3 content, with excellent design, our ceramic pulley lagging obviously increase the friction of the conveyor belt and drum.

Since ceramic tiles’ excellent water conduction performance ensures maximum drainage and mud discharge, ceramic pulley lagging is especially suitable for wet, muddy working conditions, reduce conveyor belt wear and tear, improve belt conveyor deviation

Improve the friction between the belt and roller

Ceramic pulley lagging has high wear resistance and more coverage increased the friction between rollers and belts, reducing the belt tension to extend service life so which saves operating costs.

Non-Shedding Ceramic Pieces

With advanced equipment and technology, and superior materials: (oxide content up to 95%), the adhesion between our ceramic tile and rubber is greater than 10kgf/mm2, so the ceramic tiles don’t fall off.

CN Layer doesn’t need to polish

As we only use the authentic CN Layer (Bonding Layer), Our Conveyor Ceramic Pulley Lagging doesn’t need to be sanded before use,

it can be directly bonded

Conclusion

Ceramic Pulley Lagging is a premium pulley lagging where the ceramic tiles are molded into a rubber compound. This makes for excellent traction, eliminates slippage, and offers excellent abrasion resistance. Ceramic Pulley Lagging is especially suited for drums with slippage and excessive wear & tear problems which make normal rubber pulley lagging ineffective. It is widely used in drive pulleys and can also be used on snub, bend, and tail pulleys.

We use model 95 ceramic tiles, so the ceramic pulley lagging abrasion resistance can extend more, and it ensures existing or new pulleys’ long life. As the ceramic cover area decides lagging slip resistance, Our popular type of ceramic tiles coverage reaches 45%. It provides higher belt traction & stops belt slippage even under wet & muddy conditions. And for special purposes, ceramic tiles coverage of 59%, 100%, 15% are also available

We choose excellent tile bonding chemistry to eliminate ceramic tiles loss and also use the premium rubber compound to ensure ceramic tiles have maximum flexibility and support. The design provides more grip than other ceramic pulley lagging. Customized ceramic pulley lagging strips are also provided on varying pulley diameters to reduce waste and installation time.