Conveyor Belt Vulcanizing – Definitive Guide

In the following guide, you will know everything about Conveyor Belt Vulcanizing.

During the bulk material conveying of the belt, various damages may occur due to material dumping, falls. Such as longitudinal tearing, edge damage, gouged, deep punctured, and so on. Replacing the conveyor belt will be a huge cost, so people find the method of conveyor belt vulcanizing to repair the damaged conveyor belt.

[lwptoc skipHeadingLevel=”h1″ skipHeadingText=”*Cold Vulcanizing Solution|*Hot Splicing Solution|*Featured Rubber Conveyor Belt Repair and Splicing Material|*Standard Conveyor Belt Repair Strip|*Reinforced Diamond Repair Patch|*Diamond Belt Repair Patch|*Uncured Top Cover Rubber Sheet (Top Cover)|*Uncured Intermediate Rubber (Skim Rubber)|*Belt Noodle Gum|*Project|*Factory|*Belt Splicing Company FAQ|*Are you a trader or manufacturer?|*Can I get samples to test? How does it charge?|*What is your return policy?|*What’s the lead time after we placed the official PO?|*Can you use our company logo or label?|*Which kind of certificate do you have?|*Conveyor Belt Vulcanizing – Definitive Guide|*Send Your Inquiry Today!”]

What is Conveyor Belt Vulcanizing?

Conveyor belt vulcanizing is a common method of repair conveyor belts that use physical or chemical ways to join repair materials with compromised sections of the belt. It can greatly reduce the maintenance cost, extend the lifetime of your conveyor belt system. By reducing the conveyor downtime, it can improve production efficiency.

Types of conveyor belt vulcanizing?

Conveyor belt vulcanizing can be divided into cold vulcanizing and hot vulcanizing. The cold vulcanizing splicing is fast and high efficiency, but it is only used for the emergency joint of common nylon and canvas conveyor belts. Hot vulcanizing can repair the damaged conveyor belt to its former strength, offering reduced corrosion and increased life. These two vulcanizing methods work for different conveyor belt damages and have different advantages.

Cold Vulcanizing

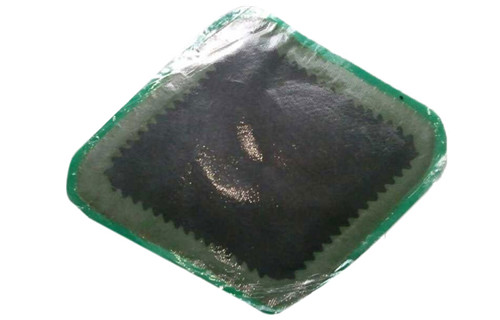

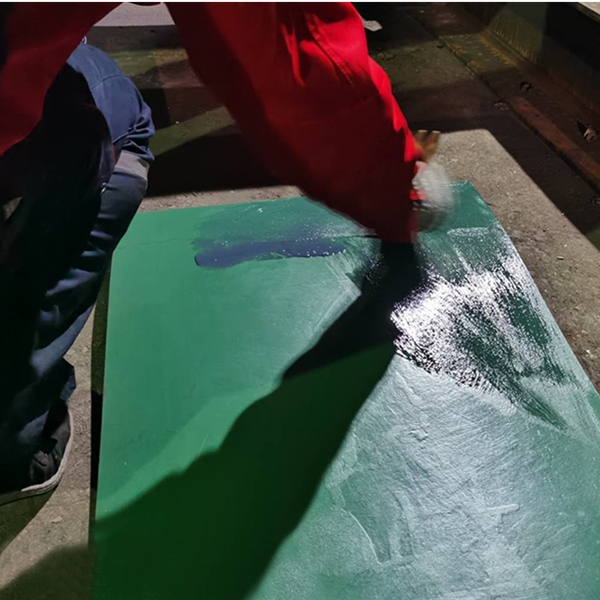

Cold vulcanizing is to use vulcanized material such as patches and strips to repair a conveyor belt. It doesn’t use a press but uses a bonding agent like TRS cold adhesive, which causes a chemical reaction to splice the two belt ends together. Cold vulcanization allows you to finish your vulcanization at ambient temperature.

You can often see it on conveyor belt jointing, pulley lagging, conveyor belt repair. Different from hot vulcanization, cold vulcanization allows your conveyor only 2-3 hours of downtime, which greatly reduces the maintenance cost and improves the production efficiency. In conveyor maintenance, cold vulcanization is a perfect solution for emergency conveyor belt repair, it suitable for conveyor belt repair includes longitudinal breaches, damaged topcoats, damaged edges of the belt, or bonding rubber to steel surface too.

Hot Vulcanizing

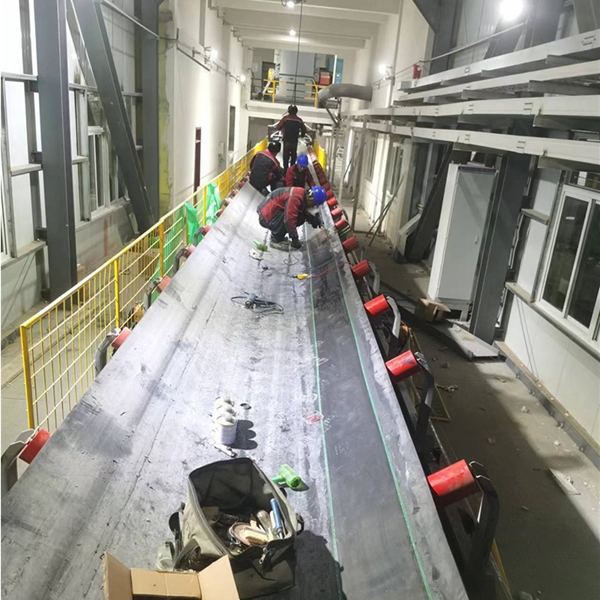

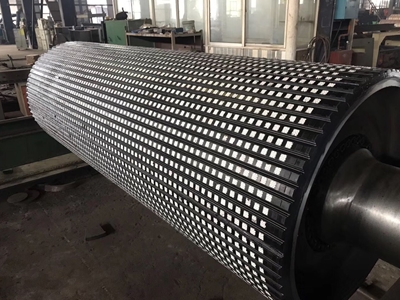

Hot vulcanizing is a method of repair that uses both heat, time, and pressure to re-splice a belt. Hot vulcanizing allows the damaged belt to its former strength, offering reduced corrosion and increased life. The hot vulcanizing procedures offer added durability that other methods lack and extend the longevity of a belt.

As it creates the highest return to original belt strength, it is ideal for splicing, cuts or tears, holes, or breakdowns between steel cords and fabric. It can be executed in dusty environments and is suitable for all types of belts with varying widths and thickness.

As the conveyor belt starts to use, it is necessary to bond two ends of the belt through splicing operation initially. Meanwhile, if the belt is worn and broken during use, it needs to trim broken parts and produce new jointing for splicing. A conveyor belt splice needs to make several times during the entire using life, hot Splicing is the best operation for conveyor belt jointing.