Conveyor Belt Hot Vulcanizing – Definitive Guide

The conveyor belt joints can be divided into two kinds: hot vulcanized splicing and cold vulcanizing splicing. The cold vulcanizing splicing is fast and high efficiency, but it is only used for the emergency joint of common nylon and canvas conveyor belts.

What is Hot Vulcanizing?

Hot vulcanizing is a method of repair that uses both heat, time, and pressure to re-splice a belt. Hot vulcanizing allows the damaged belt to its former strength, offering reduced corrosion and increased life. The hot vulcanizing procedures offer added durability that other methods lack and extend the longevity of a belt.

As it creates the highest return to original belt strength, it is ideal for splicing, cuts or tears, holes, or breakdowns between steel cords and fabric. It can be executed in dusty environments and is suitable for all types of belts with varying widths and thickness.

As the conveyor belt starts to use, it is necessary to bond two ends of the belt through splicing operation initially. Meanwhile, if the belt is worn and broken during use, it needs to trim broken parts and produce new jointing for splicing. A conveyor belt splice needs to make several times during the entire using life, hot Splicing is the best operation for conveyor belt jointing.

Conveyor Belt Hot Vulcanizing Procedure

The procedure of conveyor belt hot vulcanizing is not always the same according to the different types of conveyor belts. Usually, there are three main procedures for conveyor belt hot vulcanizing: Brush raw rubber, Paste the rubber, vulcanizing with the vulcanizing machine. Here is a detailed conveyor belt hot vulcanizing procedure:

Prepare work

First, we need to do the vulcanizing preparation work, which includes set the work platform, cut off the rubber, draws the step line, strips the cover rubber, then surface cleaning.

Set work platform

Cut off the rubber, and cut extra parts

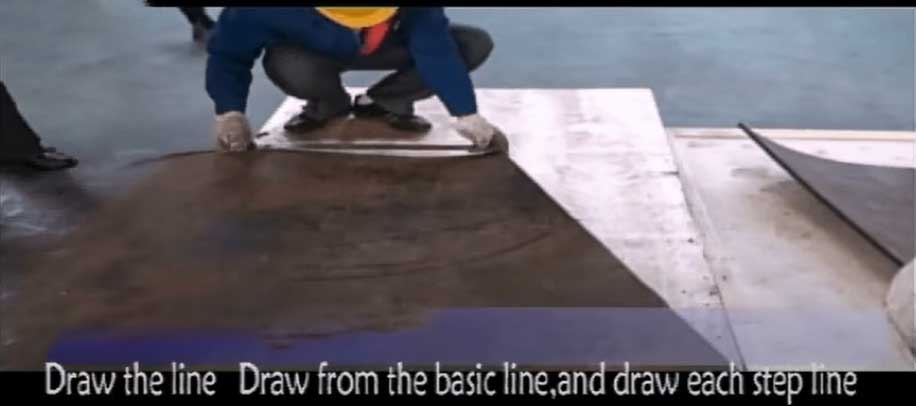

Draw the line: draw from the basic line, and draw each step line.

Strip: Strip the cover rubber and core belts, and put both sides of belts together.

Polish: polish the surface of core belts and cover rubber

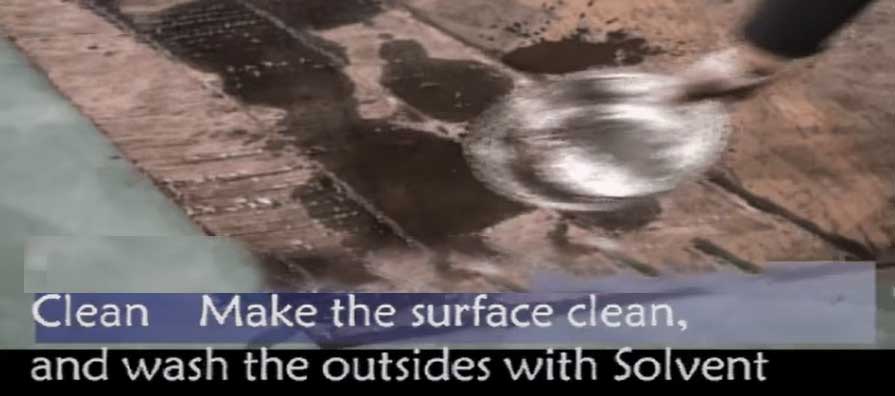

Clean: make the surface clean, and wash the outside with solvent

Place the lower heating platen, prepare as the stipulated angle

Brush the Raw Rubber

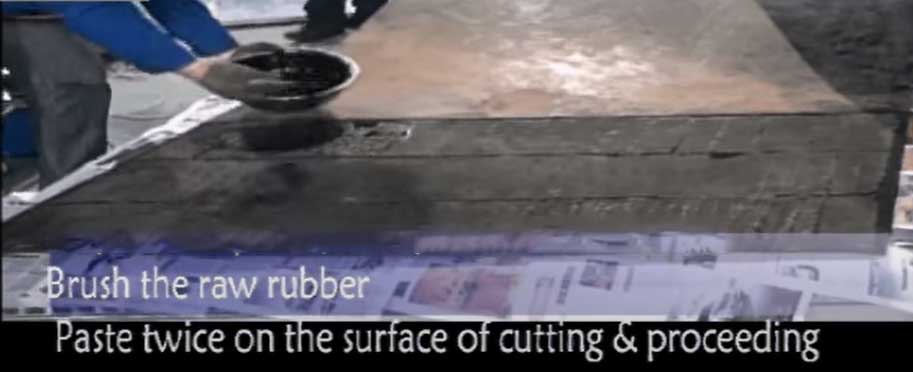

Brush 1-2 times raw rubber on the surface of the joint and vulcanized rubber. Dry it naturally. you can also use infrared or hairdryer to dry it faster. Please note that, if the raw rubber is not dry completely, it will produce bubbles, which will reduce the bonding performance.

Brush the raw rubber: paste twice on the surface of cutting & proceeding

Dry: dry it naturally (slowly), or use infrared or hairdryer

Paste the Rubber

You should paste the rubber on each step, then paste the cover rubber on the seams. Pasting from the middle of the conveyor belt to both sides can facilitate air escape from both sides. You need to make the two sides of the rubber the same degree of looseness, the steps of the joints are aligned, and the centerline is aligned.

After bonding, fully roll to prevent the accumulation of bubbles, and press the two heating plates on and down the joint to apply a certain pressure. When pressurizing, be careful not to make the joints misaligned, and the pressure should be even

Paste the rubber, paste the rubber on each step. Paste cover rubber: paste the cover rubber on the seams.

Put together: put both two proceeding surfaces together

Vulcanizing with vulcanizing machine

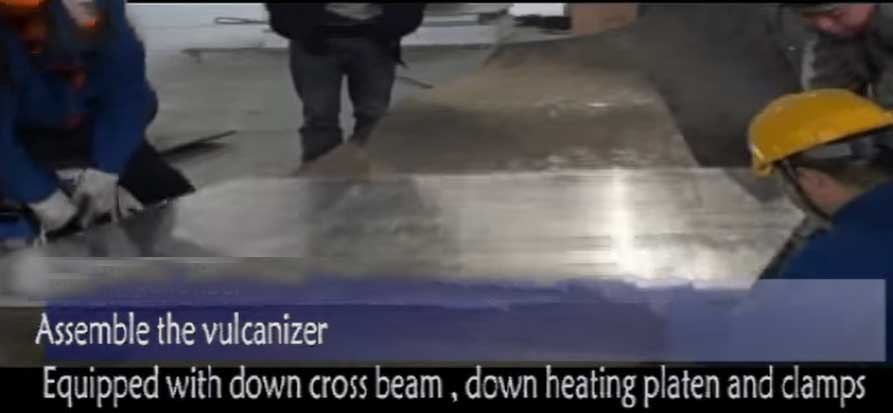

After installing the hot vulcanizing machine, heat up and pressurize. When the heating plate is heated for 15-25 minutes, press it once to ensure that the joint is under sufficient pressure. When the temperature reaches 80°C, the pressure is required to reach 1.0-2.0 MPa, then stop pressurizing and continue heating. Start timing when the temperature rises to 145°C, and the constant temperature is between 145°C and 150°C. After 45 minutes, immediately stop heating and let it cool to room temperature. Here are the detailed steps for vulcanizing procedure.

Assemble the vulcanizer: equipped with down cross beam, down heating platen, and clamps

Fastening nuts: fastening nuts of both sides tightly

Cooling: after vulcanizing, heating platens cooling below 60°C

Disassemble the vulcanizer: unfastening nuts, upper cross beams, upper heating platen

Decoration:cut extra rubber and polish to keep flat

Start to pressure: start to the required pressure (no more than 1.5Mpa)

Trimming the joint

After returning to normal temperature, remove the heating plate, and shave off the overflowing residual glue and the rubber that is higher than the surface to make the joint surface smooth and clean.

Conveyor Belt Hot Vulcanizing Application

In practical applications, the integrity of the splice is critical to minimising the risk of downtime. the Uncured Cover rubber&Uncured Skim Rubber are unvulcanized raw rubber film.

They splices with two uncured rubber to be completely after heating & pressuring by the vulcanizer, a strong belt splice relies on two important factors: the skill of the operator; and the quality of the splicing materials being used.

Our Uncured Cover Rubber& Skim rubber are designed for use in step splicing and finger splicing of belts, they are tried and tested successfully domestic

Conclusion

Hot splicing repair allows the damaged belt to its former strength, offering reduced corrosion and increased life. The hot vulcanizing procedure offer added durability that other methods lack and extend the longevity of a belt.