Belt grade and tension. With thickness. Pulley diameter. All three measurements are important when choosing the correct belt fastener for your application. But we feel that at least one other factor is important to your decision-in fact, it is so important that we wrote a blog about it. The choice of metal.

How serious are we about the choice of metals? We are serious enough to thoroughly study the wear rate of our metal products to understand their comparison. Beltcare is looking to compare the wear characteristics of its patented metal Ibeltrepair® against steel and stainless steel, specifically. This information will enable us to provide our customers with the expected average wear life of all our steel products and give them a reason to choose Magley in the most abrasive applications. But before we start testing, it is important to know what Ibeltrepair is and how it is used.

1. What is IBELTREPAIR®?

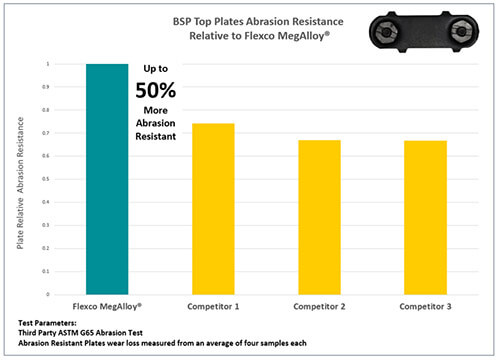

Ibeltrepair® belt buckles exceed the competition and have a 50% wear life.

Ibeltrepair contains a proprietary blend of heat-treated steel that can extend the life of joints on conveyor belts in abrasive environments. It can be used wherever abrasive materials exist, including: aggregate, granite, limestone, bagged cement, sand, tile, foundry, iron ore, metal and concrete recycling.

Of course, Ibeltrepair also has some applications where megay is not recommended, including: corrosive environments, such as citrus and phosphate; impact areas, such as under the crusher and loading area; on hot belts, the belt wears more than actual fasteners quick. In these cases, Ibeltrepair recommends the use of steel or stainless steel, depending on the application.

2. How is the testing of conveyor belt fasteners carried out

Now that you have learned about the latest situation of Ibeltrepair, you know where you should use it and where you should not use it, let’s go back to the test. We arranged the ASTM G65 wear test to be carried out in a third-party testing facility, using standard testing equipment and the Ibeltrepair® bolted solid plate fastening system. In this particular test, the fastener is first weighed. Then use the abrasive disc and the fastener for a certain number of revolutions, and measure the weight loss of the fastener after the test is completed.

In this particular test, the wear resistance is measured by taking the average of four samples from each type of metal. As the test progressed, we introduced the same fastener metal options from three Ibeltrepair competitors to understand the performance of Ibeltrepair on these three competitors.

The results of the third-party ASTM G65 wear test are not an impact for those of us who work in the field. We have seen our Ibeltrepair fasteners work in some of the most corrosive environments. But it is certainly helpful to have data to support our observations.

McGray’s performance is 50% higher than its competitors.

It is 50% better than steel, 50% better than stainless steel, and 50% better than our three competitors. In short, when you choose the right fastener for your application, you can get an average of 50% more wear life in a wear environment.

3. Why and how to test belt conveyor system products

Ibeltrepair conducts such tests to ensure that we are producing the best products for our customers-keeping their belt conveyors running at maximum efficiency and limited downtime. We test new products to ensure that they meet or exceed the quality standards we set for fasteners, and continuous product testing ensures that the products we provide are still top-notch.

We started testing our internal conveyors to measure fastener strength and joint life compared to our leading competitors. We then verify these results (if applicable) on site with third-party vendors. We also work closely with leading conveyor belt manufacturers to keep up with the latest technologies and advancements in the industries we serve.

We also test the static tensile strength of mechanical fasteners and even hinge pin fatigue to ensure that our fastening system as a whole performs at the highest level.

But Ibeltrepair’s testing is not limited to fasteners. We are testing the durability of the installation tool, the degree of wear of the cleaning blade, the strength of the belt clip, and so on. We have test platforms and test stations around the world and conduct thousands of tests every year to ensure operational efficiency, maximum productivity and employee safety.

4. Beltcare is suitable for your mechanical belt buckle application

If you want to install fasteners that can increase the wear life of your abrasive application by 50%, then Ibeltrepair can be the metal choice among Ibeltrepair’s several fastener systems. Please check our Mechanical Belt Fastening System page to see if the fastener you choose is available in McGray.

Look at this real result, how the conversion from steel to Ibeltrepair reduced downtime and saved capital for gathering quarries.

Not sure which fastener or metal is best for your application? Sign up for a free evaluation and a local representative will come to your factory to help you choose the correct belt buckle.