Key Advantages:

Rapid Curing & Fast Return to Service: T2’s chemically activated adhesive flows easily into the prepared damage area and self-vulcanizes quickly as it cools. Repairs can be completed on the spot with no waiting time for vulcanizing – conveyor belts can often resume operation the same day. This fast set time significantly cuts costly downtime and boosts productivity.

Exceptional Strength & Durability: Once cured, T2 repairs exhibit excellent resilience and abrasion resistance, delivering bond strength comparable to new conveyor belt material. The formula is formulated for wear-prone environments, so repaired areas stand up to heavy loads and abrasive conditions. Engineers and operators can rely on T2 fixes in demanding industrial settings without frequent rework or failure.

Portable & User-Friendly: The complete T2 repair system (extruder gun, AB Repair compounds, AB solution, and accessories) is lightweight and fully transportable. No special infrastructure or large equipment is needed – maintenance crews need only the handheld extruder and grinding tools. The straightforward process requires minimal training, making on-site repairs efficient even in remote or space-limited locations. This ease of use empowers crews to respond quickly to emergencies anywhere on the line.

Cost-Effective & Safe: By restoring belts in place rather than replacing them, T2 reduces repair costs and maximizes conveyor service life. Its cold-vulcanizing chemistry eliminates the need for costly kilns or heated presses. The solution is also free of harmful solvents and fumes, ensuring operator safety and environmental compliance while delivering “hot-press” quality performance.

Applicable Scenarios:

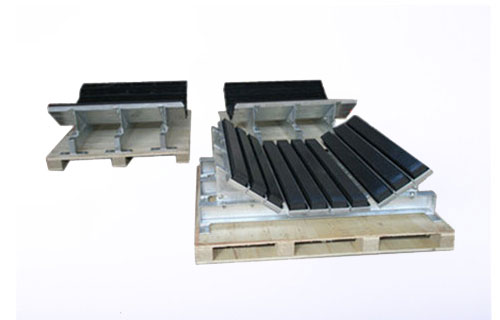

The T2 Repair System is formulated for a wide range of rubber repair tasks. It excels at patching cover damage and longitudinal tears on conveyor belts, filling V-shaped grooves in pulley lagging, and sealing gaps in rubber linings and hatches. Typical use cases include repairing belt cover cuts or abrasion, restoring drum lagging seams, fixing conveyor sealing gaskets, and even cosmetic touch-ups on rubber components. Its compatibility with natural rubber and common synthetic belt compounds (like SBR/BR blends) makes it ideal for mining, quarrying, bulk material handling, and many other industries. In practice, technicians simply clean and prime the damage zone, extrude the T2 compound strip into the cut, and allow it to cure – a process that maintains the conveyor’s service schedule.

Ease of Use

The T2 Repair System streamlines the repair workflow with simple, proven steps. After grinding and cleaning the damaged area, a thin primer layer is applied. The AB adhesive strips are then loaded into the specially designed extruder gun, which heats, mixes, and dispenses the compound precisely into the repair site. There is no hot vulcanizing oven – the mixed rubber cure is completed at room temperature. Because the extruder is fully self-contained and easy to operate, even crews without specialized belt-repair training can perform reliable fixes quickly. This simplicity speeds up maintenance cycles, minimizes labor costs, and allows belt repairs to be integrated into regular patrols and shutdowns with confidence.

Competitive Advantage

By combining speed, strength, and simplicity, T2 stands out against competing belt repair methods. Its on-demand, self-vulcanizing technology means maintenance teams get professional-quality results without the logistical headaches of hot splicing or inferior cold patches. The T2 system’s high initial elasticity and consistent properties ensure durable repairs that match factory splice performance. T2’s proven track record in mines, ports, and processing plants worldwide highlights its reliability. In addition, support from Beltcare Solution’s overseas network provides service expertise, helping operators optimize belt maintenance programs. In short, the T2 Repair System is a strategic asset – it minimizes unplanned stops and maximizes ROI by keeping conveyors running at peak efficiency.

Conclusion

As an industry-leading conveyor belt repair solution, the T2 Repair System empowers maintenance professionals to handle belt damage quickly, safely, and cost-effectively. Its innovative cold-curing formula delivers “as good as new” repairs with unmatched speed, giving plants a significant uptime advantage. Backed by professional engineering and support, T2 provides peace of mind: crews can trust their belts will run longer between replacements, and any necessary repairs will be completed with maximum efficiency.

References: Manufacturer technical data and application guides for the T2 Repair System and supporting cold-vulcanizing materials: rema-tiptop.com; ibeltrepair.com, confirm the performance claims and benefits noted here.