Materials that stick to the conveyor belt or fall from the conveyor belt to the floor or other conveyor belt components can waste time, affect quality, disrupt sanitation, challenge safety standards, etc. Many people used to include this in business costs, but more people have realized the value in belt cleaners, a step towards improving operational productivity.

1. Choosing the right cleaning agent

Recognizing this need is one thing. Choosing the right cleaner for the application is another matter. Since your maintenance team knows the details of your conveyor belt, it is natural to think that they can develop a cleaner that fits your system perfectly. Normally, this is what they do. Scrap conveyor belts, spare plastics, and even stainless steel are used to make equipment for “scraping” belts. Although this is a cheap design that can remove some of the back, it is not always the best for the health of your belt or product removed from the belt, and it is far from hygienic.

Even some engineering cleaners were unable to complete this work. They seem to be ready to meet the challenge, but are these leaves made of food-grade materials? Are there any gaps on their surfaces that may breed bacteria? Do they have a tensioning system to ensure that the blade-to-belt contact can maximize the cleaning ability?

2. How cleaners affect your efficiency

Quality, productivity, time and customer experience-these are just a few elements required to successfully operate and produce the best quality materials. Let’s discuss, a belt cleaner that is not specifically designed for food applications can sometimes do more harm than good. This is a true story.

Scenario

A local bakery company is running flatbreads on the main conveyor belt for its most important customers. The holidays are approaching, and they are expected to sell more goods than usual. There are many different styles and tastes of flatbread, and customers are proud of their freshness, so the deadline is very tight. But this operation has all the tools needed to accomplish this task? How will their newly installed light cleaners meet this challenge?

Quality

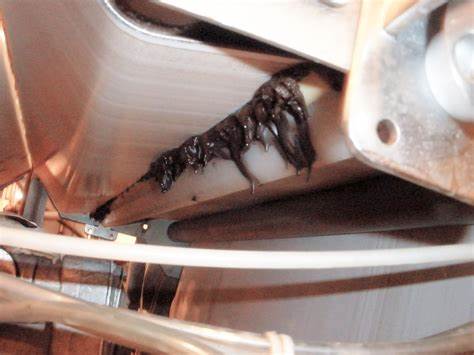

If your light belt cleaner is not cleaned well enough, you will see serious problems with product quality. Because the cleaner did not properly remove the excess dough, it was recycled, mixed with brand new dough, and also mixed with flavours, which was a serious quality problem. In many cases, such as this, the dough will be discarded.

Production efficiency

The same leftover dough will also reduce your production efficiency because the cleaner only touches certain points of the conveyor belt, and the rest of the product will fall to the floor. Their response is to clean up the fallen product and try to re-adjust the cleaning blade, rather than sending your maintenance team to do active work.

Time (and money)

When the maintenance team went to inspect the cleaner, they noticed that it was installed upside down. When they took the vacuum cleaner out, turned it over, and reinstalled it, the duct was closed. Easier said than done because it has multiple components and vague descriptions. It takes an hour and a half to repair it. Even so, they are still not sure whether it will work properly because the belt seems to be digging into the blade and there is no way to properly tension. After spending 2,000-3,000 dollars in downtime, they had to move on.

Customer Experience

They can send half of the orders to customers, but there is no guarantee that the company will receive the other half before the deadline. Customers can’t just use half of the flatbread to operate, they have to use the frozen stock they usually use to ship to customers across the country. The freshness guarantee posted on their menu will expire this weekend. They want to talk seriously about the future business with the bakery.

Now, this scene may seem like a wrong comedy, but I can assure you that it’s not funny that industrial baking operations are going through it. It is very likely that you will never encounter extreme things like this, but if any of these things happen on your conveyor belt, what are the consequences? Will you miss the deadline and throw it away because of cross-contamination Materials or recalled products? Will you lose a customer? These are unacceptable in this day and age. The competition is too fierce!

3. Correct cleaning

Most importantly, the right cleaning agent can make a big difference. It makes cleaning and sanitation an easy task, dismantling quickly and simply in less than a minute, with limited components and no need to remove the cleaner from the structure.