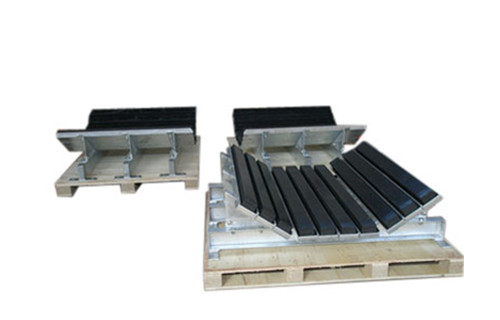

Super Screw Splice Conveyor Belt Fastening System is a new rubber conveyor belt splice method, It is a significant advancement in conveyor belt splicing, offering notable advantages such as quick installation, high stability, low consumption, and extended lifespan.