The conveyor belt repair strip is one of the most popular and cost-effective conveyor belt repair materials in recent years. It can repair the normal damages of the conveyor belt, such as a longitudinal tear, conveyor belt crack, conveyor belt pierce damage.

Beltcare Solution will show you step by step to use the conveyor belt repair strip.

1. Working Principle

Cold curing adhesive is used to paste the repair strip with CN layer on the surface of the conveyor belt, they will create a chemical reaction to cure quickly, and complete its strong adhesion to the conveyor belt.

2. Tools & Environment

Tools: Angle grinder, tungsten steel polishing plate, cold curing adhesive TRS2002, cleaning agent, rubber repair strip

Environment: Ventilated, normal temperature, and dry

Operating Steps

Your operating steps will directly affect the repair effect, please do it strictly according to the following steps:

- Grinding and Cleaning

You should calculate the grinding area first, the grinding width and thickness should be consistent with the repair strip. Then use the Angle grinder and tungsten steel polishing plate to polish the damaged surface. Finally, sweep away the residue, clean it with a cleaning agent, and dry it.

- Mix and Glue

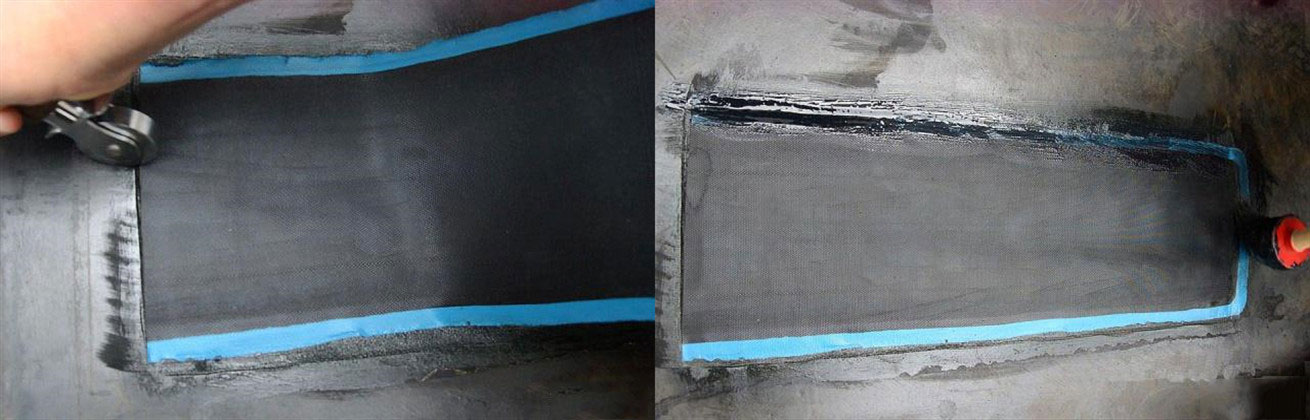

After mixing the cold curing adhesive and curing agent in proportion, evenly brush the mixture on the adhesive surface, wait some minutes, and test it with the back of your hand. If you feel slightly sticky when touching the surface, brush it again. The blue CN layer of the repair strip also needs to brush a layer of mixture.

- Bonding and curing

If you feel slightly sticky when touching the surface again, it’s time to bond it. Please paste the patch strips from one side and use a compacting roller to compacting them from the middle to the sides, it can drain the air. Finally, brush the joint evenly on the surface with the mixture.

Everything is ok, then wait 2 hours for its natural vulcanization. At this step, you can use the conveyor belt for your projects. If you can wait for 4-8 hours, it can achieve the best repair effect.

Note:

- Please note that, if there is any puncture on your conveyor belt, you should use the rubber repair agent to fix the hole first.

- During operation, the power should be cut off to avoid accidents caused by mechanical rotation. If necessary, the wheel of the reduction gear can be manually turned.

- The conveyor belt repair strip contains an organic solvent, it is low toxicity, inflammable. Fire prevention should be paid attention to in the workplace when using.

- Glue solution should not be in contact with water and must be kept fully dry, otherwise, it will affect the curing degree and bonding strength.

- Glue solution should not be bonded under the environment with a temperature of less than -40℃ or humidity greater than 80%.

Sometimes, small longitudinal tear damage may cause the whole conveyor to be penetrated. Using a conveyor belt repair strip can repair your conveyor belt without delay, it’s an indispensable tool for conveyor belt maintenance. Check here to know How to Choose Conveyor Belt Repair Strip?