Ceramic Pulley Lagging

Description

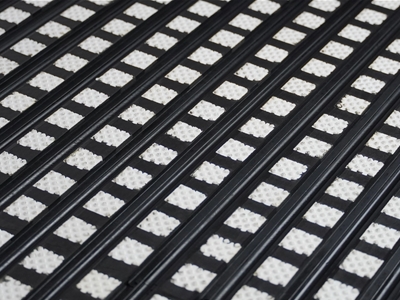

Ceramic Pulley Lagging is a premium lagging in which ceramic tiles are molded into a rubber compound. It is especially suited for pulleys with slippage and excessive wear and tear problems that make regular rubber lagging ineffective. It has the following benefits:

Enhanced Traction: Specially designed raised dimples on ceramic tiles significantly increase friction, virtually eliminating belt slippage even under wet and dirty conditions.

Extended Equipment Life: Exceptional wear resistance of alumina ceramic tiles (95% alumina) greatly prolongs pulley and belt lifespan.

Reduced Maintenance and Downtime: Superior wear characteristics reduce maintenance frequency and minimize system downtime.

Lower Operating Costs: Increased frictional efficiency allows reduced belt tension, lowering power consumption and operational costs.

Technical Specifications:

| Ceramic Tile | Rubber Compound |

|---|---|

| Alumina Content: 95% | Material: NR & SBR |

| Hardness: Mohs >9 | Hardness: 65 ± 5 Shore A |

| Working Temperature: -40°C to 85°C | Tensile Strength: 18-21 MPa |

| Elongation at Break: 550% | |

| Density: 1.15 ± 0.05 g/cm³ | |

| Wear Loss: ≤100mm³ |

Feature

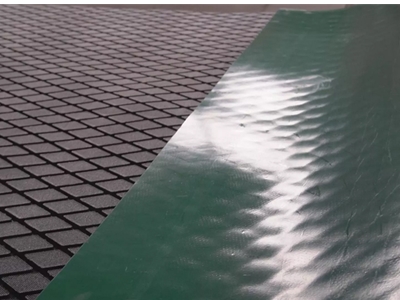

Advanced Bonding Technology:

CN bonding layer is available, significantly improving bonding strength to pulley surfaces.

Proven adhesion strength (≥12N/mm) ensures easy installation and reliable long-term performance.

Ease of Installation:

Supplied in strips (386mm or 500mm width) and rolls (up to 10 meters), minimizing joints and simplifying installation procedures.

Safety and Compliance:

Fully meets FRAS standards for flame resistance, suitable for underground mining applications.

Certified according to ISO9001:2015.

Applications

Drive/Tail Pulleys: Prevents slippage in high-tension systems.

Snub/Bend Pulleys: Improves tracking in wet/dirty conditions.

Mining/Underground: MA-approved for flame resistance