Description

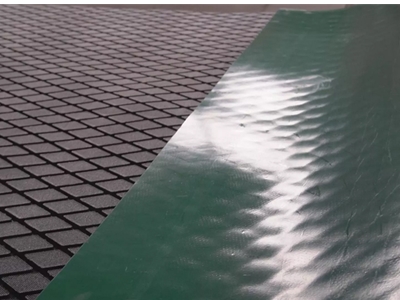

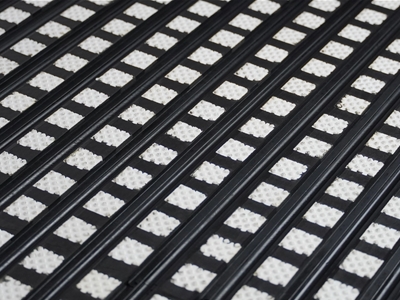

Diamond Rubber Pulley Lagging is made from a high-quality wear-resistant rubber synthesized from IR, BR, and SBR. The rubber has a dense structure, soft texture, and good resilience, it can be used for extended life periods under normal working conditions without aging. The diamond pulley lagging comes with a Bonding Layer for better adhesion levels, it is often applied to extend the life of the shell by providing a replaceable wearing surface or to improve the friction between the belt and the drum. It can also be used for spare pulleys when one doesn’t know the direction of rotation. The FRAS and oil-resistant types are available on request.

Specifications:

- Thick:10mm,12mm,15mm,20mm,

- Width.:1000mm. 2000mm ;

- Length can be customized.

Feature

Wear Resistance: The diamond patterns enhance the wear resistance of the rubber pulley lagging, effectively protecting the roller surface from wear

Reduced Belt Slippage: The diamond patterns provide additional friction, increasing the traction between the roller and the conveyed material, and preventing slippage and misalignment.

Extend Conveyor Belt and Drum Service Life

Application

The diamond rubber pulley lagging is designed primarily for use as lagging of conveyor belt pulleys to increase grip and reduce wear and corrosion of the Drive Drums shell. It is commonly used in high-load, high-speed applications requiring strong anti-slip properties, such as mining, coal, and construction. It is also used in the following industries: cement, quarrying, metals processing, power industry, port industry, steel industry, Chemical, etc.

In conclusion, the diamond rubber pulley lagging is widely used in various material conveying systems that require high wear resistance, anti-slip properties, and long service life.