The conveyor pulley is an indispensable part of the belt conveyor and assembly line equipment. The conveyor pulley lagging materials are used to protect the drum from erosion and extend the drum service life. The conveyor drum is easy to slip into the high-strength conveying system.

When choosing pulley lagging materials, you need to take a holistic view of pulley laggings, adhesive, and pulley lagging technologies.

The pulley laggings usually include Ceramic Pulley Lagging, Diamond Pulley Lagging, Plain Rubber Pulley Lagging, Slide Pulley Lagging, etc. And the glues are usually made of Natural rubber, neoprene rubber, polyurethane, etc.

The traditional pulley lagging method generally includes cold bonded pully lagging and hot vulcanization pulley lagging. These two lagging types are more expensive and more harmful to the pulley.

At present, most companies are using cold vulcanized pulley lagging technology, it can finish the lagging without removing the pulley. It can reduce the work intensity a lot and save the downtime of the conveyor belt.

The different lagging method has different lagging materials, Beltcare solution will show you the materials for cold vulcanization according to the pulley lagging process. If you want to know all the details of the pulley lagging process, you can check this article: A Complete Guide for Conveyor Pulley Lagging Installation

1. Cleaning Cement

Before you start your cold vulcanization lagging, you need to use the cleaning solvent to remove the residual glue on the surface of the pulley first.

Then, you need to use the Angle grinder with a tungsten steel disc to polish the surface of the pulley to increase the surface roughness. I.E: TRS

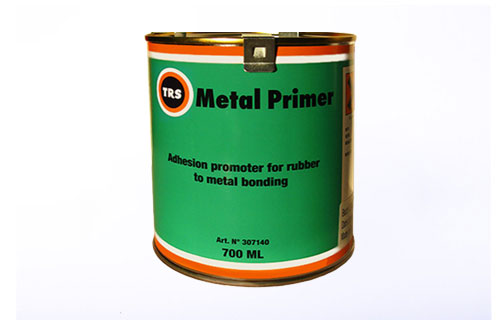

2. Metal Primer

After the cleaning solvent dries, quickly brush a layer of metal treating solvent on the surface of the pulley, it can not only protect the pully metal surface from erosion but also increase the wettability of subsequent coating glue.

3. Cold Vulcanizing Cement, Conveyor Rubber Pulley Lagging

After the metal primer is dried, brush the mixed two-component cold bonding glue on the metal surface of the pulley, you should brush it twice. The wear-resistant rubber pulley lagging also needs to brush with cold vulcanizing cement.

4. Bonding the pulley lagging

When the glue is slightly stuck to the finger’s back, stick the rubber pulley lagging on the durm surface, then use a rubber hammer to beat it. Please make sure your beating process is strong enough.

At this step, you can cut the joint part of the rubber lagging into a “V-shaped mouth” with a rubber knife. After that, fill a small part of mixed rubber repair adhesive in the joint part to make the sealing, then use a compaction roller to make e sealing part firm.

5. Conclusion

The cold vulcanized pulley lagging materials include wear-resistant rubber pulley lagging. cold vulcanizing adhesive, metal primer, cleaning solvent, etc tools