Conveyor systems are used as standard parts of mechanical handling equipment in many industries, it can move goods, products, and raw materials from one place to another, usually in the same area or in the same building.

The performance of the conveyor belt determines the main application of the conveyor belt, here are some of the most widely used conveyor belts and their applications:

1. Solid Conveyor belts

The solid conveyor belt is one of the most common general-use conveyor belts. Typical characteristic materials for these solid belts include rubber or fabrics such as nylon, polyester, neoprene, or nitrile.

It is widely used in many different industries, such as Mining, Logistics, Aircraft, etc. Conveyor belt repair materials are used to repair this type of conveyor belt.

For example, the mining and milling industries often use rubber to process bulk materials, including raw ore and aggregates. Grocery stores usually use PVC conveyor belts, and airports may use neoprene, polyester, or rubber to handle luggage.

Conveyor belt manufacturers use materials with different coatings, thicknesses, and arrangements to produce different conveyor belts with different performances.

For example, some conveyor belts need to meet the requirement of food safety ratings, while some need performs well at high temperatures.

The common characteristics of general-purpose belts include high or low friction levels and specific bulk handling structures.

2. Filter Conveyor Belt

Filter conveyor belts allow particles to pass through rather than along the conveyor belt system. It can be used in industry to drain excess liquid from components or filter out toxins. Besides, water treatment companies often use these types of conveying systems in the water treatment process. Manufacturers can use metal or synthetic fibers to produce filter-capable belts.

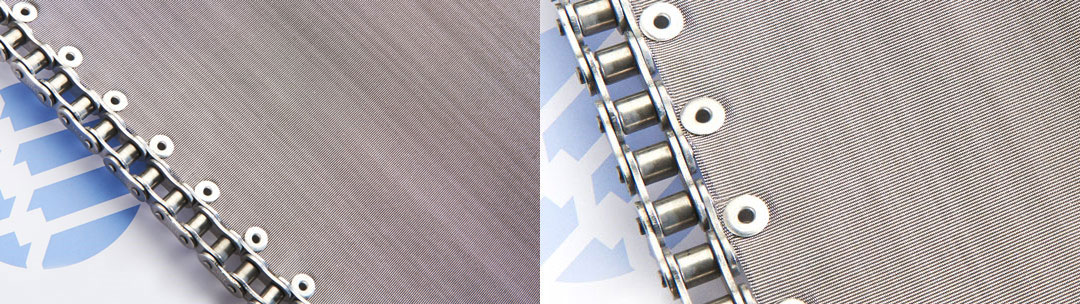

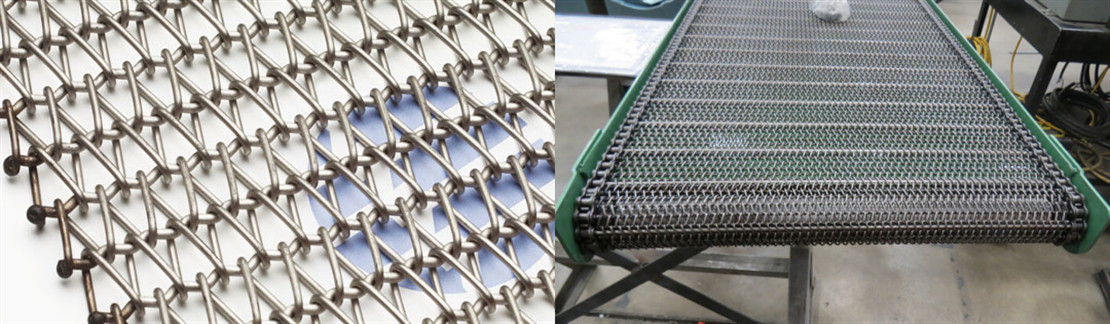

3. Woven Metal Conveyor Belt

A woven metal conveyor belt is designed to allow airflow as an item moves along, it features interlinking chains of metal or wiring. In industries such as food, electronics, and glass processing, companies often use woven metal conveyor belts to facilitate the drying, cooling, and heating processes.

The woven metal conveyor belt manufacturers can provide prefabricated or custom woven belt designs to meet customer-specific application requirements.

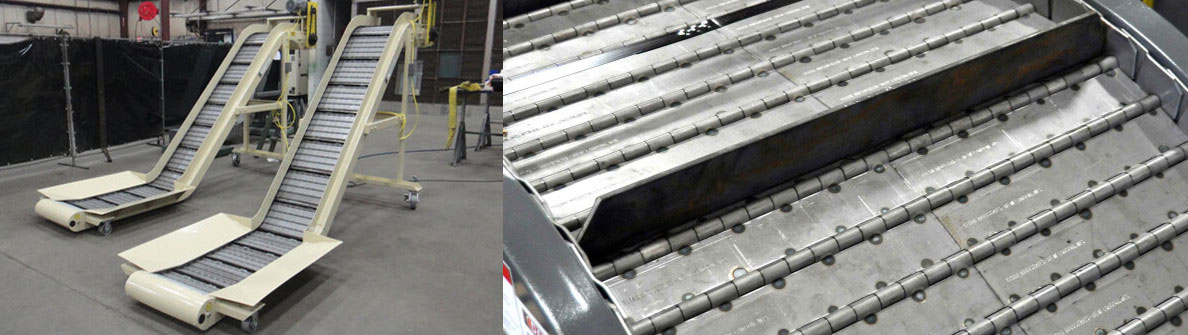

4. Hinged Conveyor Belts

Hinge conveyor belts are usually characterized by metal structures. The hinged quality belt gives it a flat, solid surface that can rotate around the pulley system via interlocking hinges. The metal hinge conveyor belt is durable and can withstand rigorous use, people use hinge conveyor belts for small products, scrap, and recycling applications.

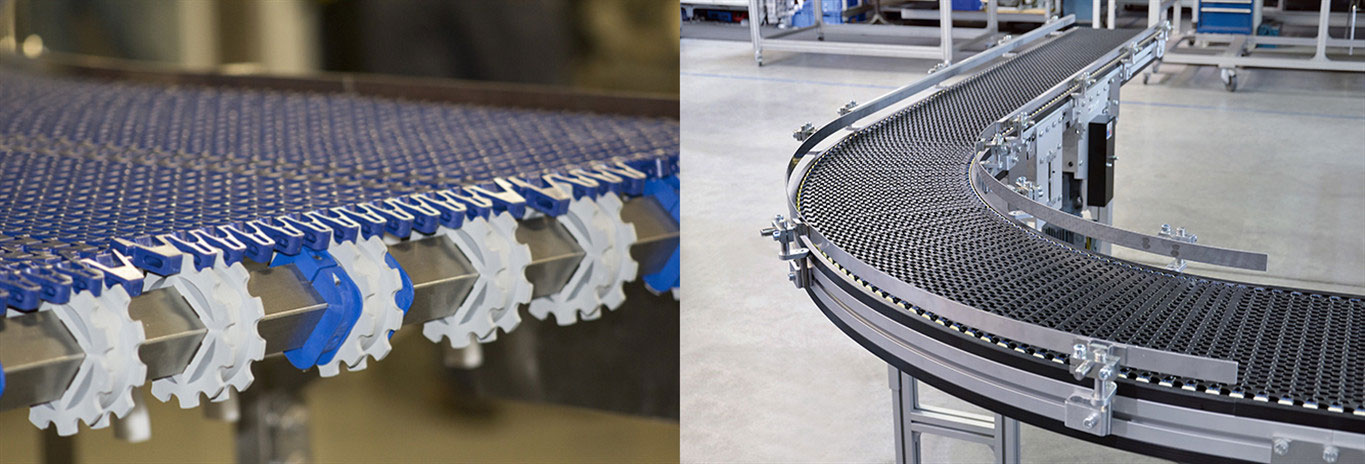

5. Plastic Interlocking Conveyor Belts

Plastic interlocking conveyor belts provide a modular alternative to metal and fabric belts for manufacturers and material handlers. It usually needs frequent cleaning and belt replacement. People use plastic interlocking belts in food handling and packaging processes or in the automotive industry.

6. Conclusion

The application always determines the material, structure, and style of the belt used. Choosing the right conveyor belt system will benefit your business a lot and can extend the lifetime of your conveyor belt. Please make sure your conveyor belt supplier has a good understanding of the application’s details and unique specifications, they will make a customized solution for you.