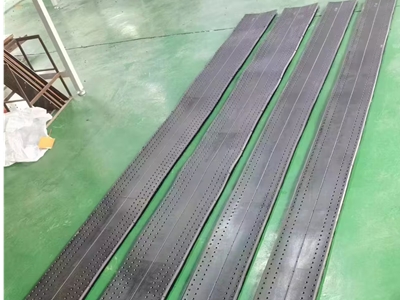

What is the conveyor roller pulley lagging? Roller lagging is an essential component and integral part of belt conveyor transportation systems. After the rollers are covered, they can effectively improve the operation of the conveyor system, protecting metal rollers from abrasion. Generally, the pulley lagging materials including the Diamond pattern pulley lagging, herringbone pattern pulley lagging, and ceramic pulley lagging, these conveyor pulley laggings can increase friction on the rubber surface, effectively preventing sliding friction between the roller and the belt. This reduces belt slippage and minimizes material adhesion on the roller surface, consequently reducing belt misalignment and wear, and enhancing operational efficiency. they ensure that the rollers and the belt operate in synchronization, thereby guaranteeing efficient and high-capacity belt operation.

For each type of conveyor pulley lagging, there’re many sizes. such as Conveyor Diamond/Plain Rubber Pulley Lagging, the thickness ranges include 10mm, 12mm,15mm, and 20mm; for Conveyor Ceramic Pulley Lagging, the thickness ranges include 12 mm,15mm, and 20mm.

How to select the suitable conveyor pulley lagging sheet’s thickness? Please check the following introduction :

The thickness of the conveyor rubber pulley lagging will depend on the diameter of the roller. Generally, larger roller diameters require thicker conveyor pulley laggings for protection.

Here are the standard thicknesses for conveyor rubber pulley lagging based on roller diameter:

- Roller diameter ≤ 630mm: Conveyor Pulley Lagging thickness of 10mm

- Roller diameter 630mm-800mm: Conveyor Pulley Lagging thickness of 12mm

- Roller diameter 800mm-1000mm: Conveyor Pulley Lagging thickness of 15mm

- Roller diameter ≥ 1000mm: Conveyor Pulley Lagging thickness of 20mm

It’s important to note that the pulley lagging’ rubber used for the roller has good resilience. Therefore, excessively thick conveyor rubber pulley laggings are not recommended as the strong rebound force can cause the rubber coating to peel off. This not only fails to protect the roller but also increases its load.

Commonly used thickness specifications for wear-resistant plain rubber pulley lagging and wear-resistant diamond rubber pulley lagging include 10mm, 12mm, and 15mm. Wear-resistant Conveyor Ceramic pulley lagging is often used with thickness specifications of 12mm, 15mm, and 20mm