How many years is the service life of a conveyor belt? The longest service life of conveyor belt among our customers is 12 years, but most customers can not use it for such a long time. One of the most important factors affecting the conveyor belt is daily maintenance.

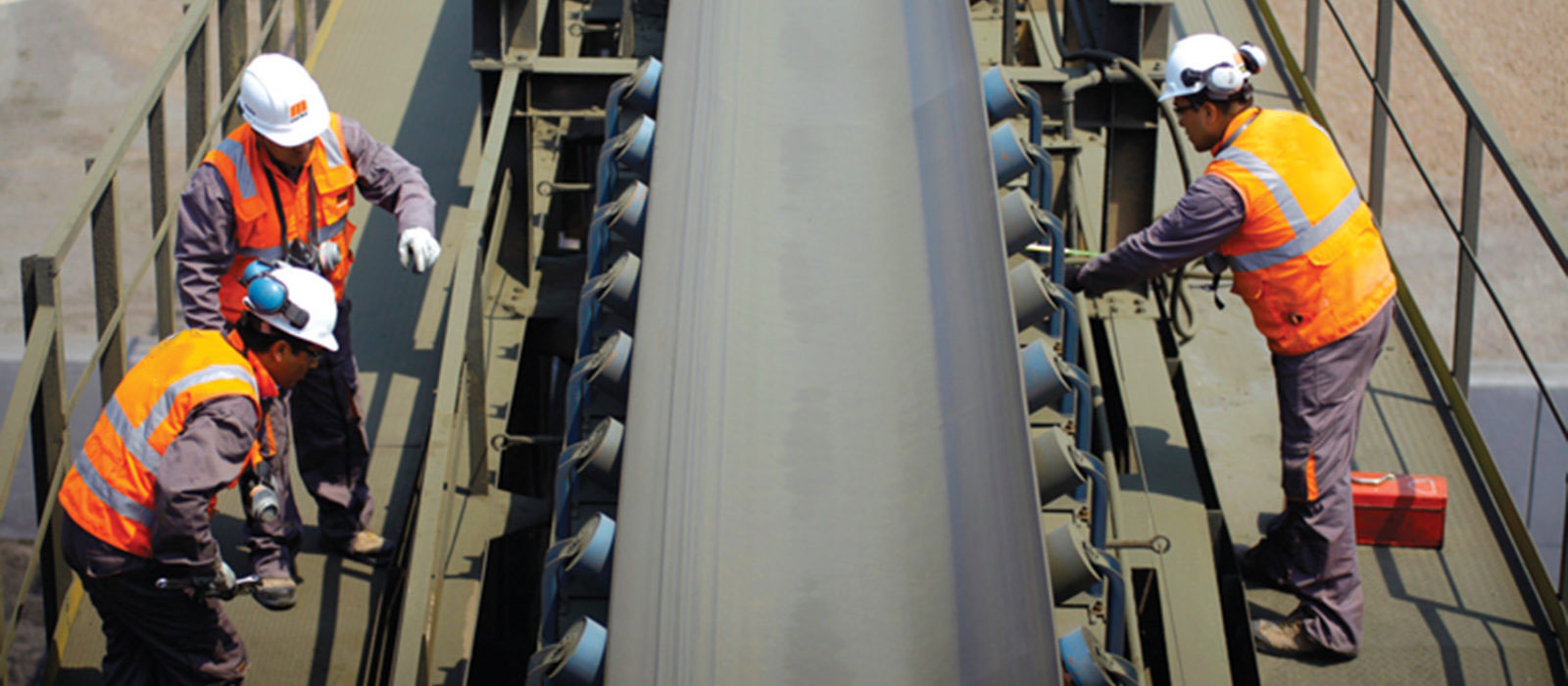

A small conveyor belt problem may shut down the conveyor system, and cause huge losses to the factory. Keeping good preventive conveyor maintenance can not only reduce plant operating costs but also ensure those belt conveyors have a long, trouble-free service life.

The conveyor maintenance includes quarterly maintenance, monthly maintenance, weekly maintenance, daily maintenance. Some conveyor items even need to maintain every two days. You need to follow comprehensive maintenance procedures to prevent unplanned downtime. Here is a maintenance checklist that lists all conveyor components for regular inspections.

1. Three Principle for Conveyor Belt Maintenance

The best maintenance for conveyor belt base to a good understanding of your equipment. 3 principles can help you maintain your conveyor in an orderly way.

Arranging A Special Engineer For conveyor maintenance

Consider the workers may not pay much attention to the specific management of the conveyor running, it easy to ignore some inspections, and it will directly affect the use of equipment. Arranging an engineer for your conveyor maintenance will help the plant to know all the things about the conveyor system running.

Building Conveyor Belt Management System

Although the management just for equipment, building a total conveyor belt management system can not only solve problems on time but also reduce the gratuitous damage to the conveyor belt. A great management system can ensure the right operations, and finally, guarantee production safety.

Doing Well Related Management Work

Consider each conveyor component, doing all the related management work is not an easy thing. You need to make a checklist that lists all conveyor components for regular inspections, make sure that all the management work has been done.

2. Preventive Maintenance Checklist

While many maintenance tasks only require quarterly or annual servicing, it is imperative to regularly inspect every conveyor component to detect malfunctions or miscalibrations. Below, we provide a comprehensive monthly conveyor system maintenance checklist base on the time.

Daily Maintenance

Whether the conveyor belt and joints are abnormal.

Whether the conveyor belt is cut, cracked, pierced, or damaged by other reasons.

Whether there is interlayer peeling damage, especially at the joints.

Whether the core body has broken parts.

Whether the upper and lower cover rubber is worn, especially the upper cover rubber, check whether the coal baffle is in contact with the surface of the conveyor belt.

Whether the conveyor belt has half abrasion.

Whether there is wear on both sides of the conveyor belt.

Weekly Maintenance

Check the wear of the conveyor belt: the checkpoint should be a certain distance away from the joint

Check the operation status

Whether the conveyor belt and the bracket are worn due to the deviation of the conveyor belt

Whether the material has a partial load phenomenon

Whether the conveyor belt sag between the rollers is normal

Is there any phenomenon of the overflow of materials on the conveyor belt due to the distance between the rollers is too large?

Whether the conveyor belt is wrinkled and sagging

Whether the conveyor belt is slipping on the driving roller

Determination of elongation: at the beginning of the operation, check whether the tensioning device is effective. After one month, check it once a month. After three months, check twice a year. When checking the tensioning device, you need to measure the distance between the standard lines of the conveyor belt.

Check the Joint Appearance: check whether there are any abnormal phenomena, including trauma, bumps, etc. When checking, you need to put the joint part in a position with low tension.

Check the loading point: Check whether the position of the buffer roller is correct, and whether the gap between the baffle plate and the conveyor belt is appropriate

Maintenance Every 2 Days

Check the cleaning device: Check whether the scraper moves well, and is there any material on the rollers and idlers.

Check the roller idlers: Check whether the bearing is damaged or lack oil, and make sure that the movement is normal, and replace the worn idler in time.

Monthly Maintenance

The most comprehensive conveyor maintenance is the monthly maintenance, the maintenance checklist should include a drive motor, motor mounting bolts, gearbox, bearings, and V-belts. Any signs of abnormal vibration or noise need to pay immediate attention to avoid future failures. Adjust the transmission chain and conveyor belt to make it track correctly. Make necessary adjustments to both

Quarterly Maintenance

Comprehensive structural safety inspections and lubricants are part of each quarterly inspection checklist. Check the entire length of the conveyor structure for signs of damage or loose hardware. The specific inspection area includes bearings and bearing mounting bolts. Check the head and tail wheel fixing screws and installation hardware.

Before resuming the operation of the conveyor, replace the missing hardware and repair the damaged parts. Lubricate the bearings with grease or oil along the entire length of the conveyor-depending on the type of bearing and the manufacturer’s recommendations.