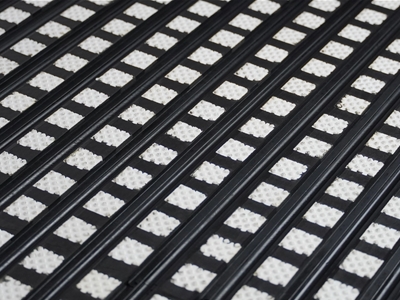

Ceramic pulley lagging is a significant upgrade over conveyor rubber pulley lagging, offering a combination of high friction and durability that is valuable in mining, quarrying, and heavy industry. By effectively preventing belt slippage, it delivers more consistent conveyor drive performance, meaning belts run at the correct speed without jerking or stalling. At the same time, its toughness against abrasion and excellent bonding make it last longer and protect the roller from damage, even under conditions that would cause rapid failure of normal lagging. Whether dealing with water spray, slurry, or simply the need for greater power transmission, ceramic pulley lagging provides a proven solution that improves belt traction, keeps conveyors aligned, and reduces maintenance

-

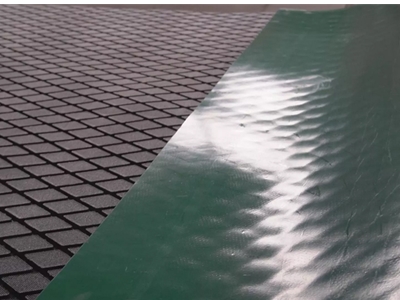

Diamond Rubber Pulley Lagging is the most commonly used lagging sheet, it is suitable for lagging drive rollers of fabric conveyor belts and high-strength steel cord conveyor belts. It features diamond patterns engraved on a wear-resistant rubber base, providing higher friction than plain rubber pulley lagging. This increased friction enhances the power output efficiency and stability by improving the friction between the drive roller and the conveyor belt. and the diamond rubber pulley lagging is pre-grooved, with diamond-shaped grooves that expel debris, protecting the roller from material adhesion and preventing conveyor belt slippage.

Diamond Rubber Pulley Lagging is the most commonly used lagging sheet, it is suitable for lagging drive rollers of fabric conveyor belts and high-strength steel cord conveyor belts. It features diamond patterns engraved on a wear-resistant rubber base, providing higher friction than plain rubber pulley lagging. This increased friction enhances the power output efficiency and stability by improving the friction between the drive roller and the conveyor belt. and the diamond rubber pulley lagging is pre-grooved, with diamond-shaped grooves that expel debris, protecting the roller from material adhesion and preventing conveyor belt slippage. -

Plain rubber pulley lagging sheet is a smooth, non-grooved lagging designed for conveyor systems worldwide. It is ideal for non-driving (idler/tail) drums, providing a flat, rubberized surface that extends drum life and prevents material buildup. By maintaining even belt contact without excessive friction, plain rubber lagging keeps the belt tracking smoothly and reduces wear. This makes it a reliable, cost-effective solution in mining, power plants, ports, chemical, and light-industry conveyors globally

Plain rubber pulley lagging sheet is a smooth, non-grooved lagging designed for conveyor systems worldwide. It is ideal for non-driving (idler/tail) drums, providing a flat, rubberized surface that extends drum life and prevents material buildup. By maintaining even belt contact without excessive friction, plain rubber lagging keeps the belt tracking smoothly and reduces wear. This makes it a reliable, cost-effective solution in mining, power plants, ports, chemical, and light-industry conveyors globally