-

Uncured Intermediate Rubber(tie gum) is designed to bond to cured cover rubber in all standard grades of steel cord and fabric conveyor belts. Uncured intermediate rubber used for hot splicing is formulated to withstand the vulcanization process and to adhere effectively to the conveyor belt's carcass or core material. It needs to have the necessary properties, including heat resistance and adhesion, to ensure a reliable belt hot splicing

Uncured Intermediate Rubber(tie gum) is designed to bond to cured cover rubber in all standard grades of steel cord and fabric conveyor belts. Uncured intermediate rubber used for hot splicing is formulated to withstand the vulcanization process and to adhere effectively to the conveyor belt's carcass or core material. It needs to have the necessary properties, including heat resistance and adhesion, to ensure a reliable belt hot splicing -

Uncured Cover Rubber (Cover Rubber Sheeting uncured) is an uncured rubber for conveyor belt hot splicing. It is designed for use as a cover rubber replacement material in splicing steel cords and fabric conveyor belts. the uncured cover rubber(Cover Rubber Sheeting uncured) has the following advantages: Wear Resistance Enhancement; Core Layer Protection; Prevention of chemical corrosion of uncured intermediate rubber, and Operational Efficiency

Uncured Cover Rubber (Cover Rubber Sheeting uncured) is an uncured rubber for conveyor belt hot splicing. It is designed for use as a cover rubber replacement material in splicing steel cords and fabric conveyor belts. the uncured cover rubber(Cover Rubber Sheeting uncured) has the following advantages: Wear Resistance Enhancement; Core Layer Protection; Prevention of chemical corrosion of uncured intermediate rubber, and Operational Efficiency -

The T2 System Glue Extruder Gun is primarily used for repairing rubber damage on conveyor belts, including surface abrasions, cracks, and non-penetrative longitudinal tears in steel cord belts. The T2 System Glue Extruder Gun is an indispensable and irreplaceable tool in the T2 cold vulcanization repair system. Its primary function is instantly mixing and extruding T2 compound adhesive for immediate application, making it a key component of the repair process.

The T2 System Glue Extruder Gun is primarily used for repairing rubber damage on conveyor belts, including surface abrasions, cracks, and non-penetrative longitudinal tears in steel cord belts. The T2 System Glue Extruder Gun is an indispensable and irreplaceable tool in the T2 cold vulcanization repair system. Its primary function is instantly mixing and extruding T2 compound adhesive for immediate application, making it a key component of the repair process. -

The T2 Repair AB Compound Strip is a specialized two-component cold bond repair solution designed for efficient and durable repairs of rubber components, particularly in industrial settings.It is applied using the T2 Compound Extruder Gun and self-vulcanizes at ambient temperatures (minimum 18°C), requiring no additional vulcanization.

The T2 Repair AB Compound Strip is a specialized two-component cold bond repair solution designed for efficient and durable repairs of rubber components, particularly in industrial settings.It is applied using the T2 Compound Extruder Gun and self-vulcanizes at ambient temperatures (minimum 18°C), requiring no additional vulcanization. -

Rubber Repair Strip (Repair Patch) is made of synthetic rubber compound with a superior quality semi-vulcanized bonding layer on one side. It is a highly wear-resistant, natural rubber strip designed to repair damage to the conveyor belt. As the authentic CN layer(bonding layer), the Adhesive Force reached about 9N/mm after bonding 72 hours. and the CN layer's featured characteristic is that its adhesive force increases with time, while the adhesion of the inferior CN layer adhesion force doesn’t change over time.

Rubber Repair Strip (Repair Patch) is made of synthetic rubber compound with a superior quality semi-vulcanized bonding layer on one side. It is a highly wear-resistant, natural rubber strip designed to repair damage to the conveyor belt. As the authentic CN layer(bonding layer), the Adhesive Force reached about 9N/mm after bonding 72 hours. and the CN layer's featured characteristic is that its adhesive force increases with time, while the adhesion of the inferior CN layer adhesion force doesn’t change over time. -

Reinforced Diamond Repair Patches have an extremely tough cover stock and beveled edges, they are mainly used for maximum puncture resistance. They are used in the event of small or large damages on rubber linings of conveyor belts. Reinforced diamond repair patches especially better used for repairing damages that request higher tensile strength

-

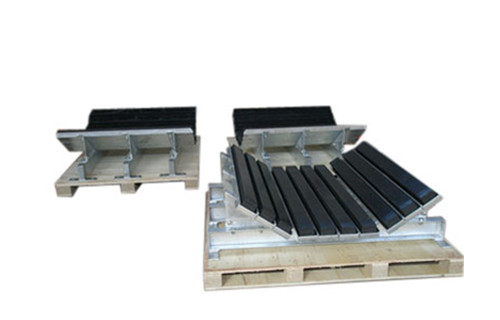

The primary belt cleaner is installed under the center line of the head drum. It is suitable for primary cleaning of materials with large water content, and for one-way operation, cleaning of the conveyor belt of mechanical, cold, or hot vulcanized joints, protecting the belt from damage and prolonging the service life of the belt.

The primary belt cleaner is installed under the center line of the head drum. It is suitable for primary cleaning of materials with large water content, and for one-way operation, cleaning of the conveyor belt of mechanical, cold, or hot vulcanized joints, protecting the belt from damage and prolonging the service life of the belt. -

Plain rubber pulley lagging sheet is a smooth, non-grooved lagging designed for conveyor systems worldwide. It is ideal for non-driving (idler/tail) drums, providing a flat, rubberized surface that extends drum life and prevents material buildup. By maintaining even belt contact without excessive friction, plain rubber lagging keeps the belt tracking smoothly and reduces wear. This makes it a reliable, cost-effective solution in mining, power plants, ports, chemical, and light-industry conveyors globally

Plain rubber pulley lagging sheet is a smooth, non-grooved lagging designed for conveyor systems worldwide. It is ideal for non-driving (idler/tail) drums, providing a flat, rubberized surface that extends drum life and prevents material buildup. By maintaining even belt contact without excessive friction, plain rubber lagging keeps the belt tracking smoothly and reduces wear. This makes it a reliable, cost-effective solution in mining, power plants, ports, chemical, and light-industry conveyors globally