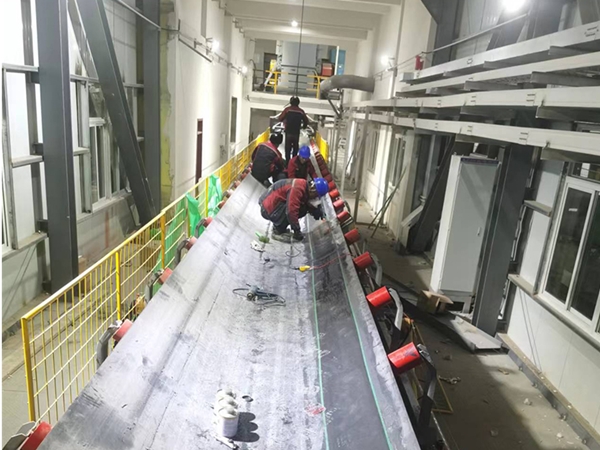

Conveyor belt cleaner maintenance is tight. You have done your homework, so you have the right cleaner in place. It is your responsibility to ensure the primary cleaners are in the right place, and the secondary cleaners are in the right place to do their best. Your team installs them carefully, so they are correct. So you are done, right? They will do their job until they don’t do it, and then you can replace them. Actually, it doesn’t need to be this way.

Compared with installed and ignored cleaners, actively maintained cleaners are more likely to run longer and less likely to cause damage to belts and fasteners until they need to be replaced.

Carrying is the main contributor to the cost of maintaining your belt conveyor. Actively maintained belt cleaners can solve any carrying problems that may occur on your system, while extending the life of your other components.

1. Cleaner maintenance…simplified

When cleaning and maintaining, there are three simple principles to keep in mind: clean, check it, and tension it.

Clean it

The maintenance of the conveyor belt cleaning machine sounds obvious, but the first principle of using the cleaning machine is to remove any debris on the blades and tension springs. The cleaner will fall off most of the strap to the chute or receiving belt, but sometimes it will fall on the cleaner itself. When debris is stuck on the tensioner, the tensioner cannot work properly, and removing the accumulated material on the blade makes the tensioner more effective. In addition, dust-free cleaners are easier to check.

Inspect it

A simple visual inspection of the conveyor belt can do wonders for the cleaning staff. You can check to see if everything is normal and replace the damaged parts. When it comes to the blade, check the visual wear line to ensure that the blade has not reached the end of its life. When you check the blade, record how close you are to complete wear and the approximate time it takes to reach this wear point.

Tension it

Conveyor belt cleaning machine tension blade to adapt to blade wear and get the best cleaning performance. In most cases, this is quick and easy to do, by checking the cleanliness of the sticker on the reference tension and measuring the tension spring to ensure proper tension of the blade. If no decals are present, a simple check operation manual should provide the answers you need.

2. Proactive maintenance should not stop here

It is important to remember that the success of any conveyor belt system depends on your conveyor belt and components working as a complete system. Choosing a product that works as a whole is indispensable to the performance and safety of the system. Routine maintenance and evaluation of your system is a sign of any effective operation-ultimately saving you time and money. Proactive maintenance should not stop here.