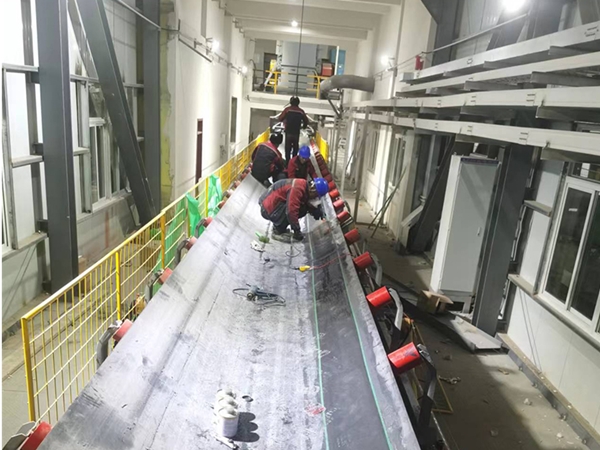

The conveying system systematically conveys materials, usually in an industrial or controlled environment. The conveyor belt is a reliable energy-saving device designed to increase efficiency. Let’s take a look at how conveyor belts work and why they can stand the test of time.

1. How the conveyor belt works

The working principle of the conveyor belt is to use two electric pulleys to wind around a long section of thick and durable material. When the motor on the pulley runs at the same speed and rotates in the same direction, the transmission belt moves between the two.

If the objects are particularly heavy or bulky, or if the conveyor belt will transport them for a long distance or for a period of time, you can place idlers on both sides of the conveyor belt to support them.

2. Conveyor system part

Although there are many types of conveying systems, all serve the same purpose of transporting materials. Some products may require a system without belts, using only rollers or wheels for flexible movement. Conveyor systems, on the other hand, typically use a belt frame and support rollers to efficiently transport products and materials.

All conveying systems have three main components-aluminum profile, drive unit and end unit.

In the conveyor belt system, the aluminum profile is composed of a frame, a belt, and any brackets. The conveyor belt system is usually driven by a motor, but the conveying system can also be operated by gravity or manually. Electric conveyor belts are ideal for industrial use because they are more reliable and efficient-the drive unit of this system will include the motor support, electrical drive and any counter bearings.

The end unit of the conveyor belt system usually includes any pulleys and clamping belts. For specific changes or functions, additional brackets or lateral guidance may be necessary, so when choosing these optional add-ons, you should consider your industry needs. The parts and functions of a new conveyor belt system may include:

- Frame: The frame of the system fixes all moving parts together to ensure safe and reliable operation.

- Conveyor belt: a long section of thick and durable material through which the material can be transported from one place to another.

- Conveyor belt support: The idler assists the conveyor belt to stay on the track and quickly keep moving. The roller keeps the position of the object and prevents the belt from sagging.

- Transmission: The motor can use variable speed or constant reduction gears to drive the conveyor belt. An efficient drive unit must continuously help the belt run continuously, change direction smoothly and adjust direction repeatedly.

- Pulleys: The conveyor belt should be wound on two or more strategically located pulleys. The pulley controls the movement of the belt and performs key functions such as driving, redirecting, steering, tensioning and tracking the belt.

- Clamping band: Clamping bands are used on various machines to fix fixtures and working parts.

- Add-on modules: Install most of the additional components for further enhancement. Ina system with rollers, brackets and lateral guides support the outer frame while the rollers support the belt from the inside.

Conveyor belts can be made of various materials, including rubber, metal, leather, fabric, and plastic. Consider the conditions under which your system will operate to ensure that the conveyor belt material is of the appropriate thickness and strength.

3. The function of the conveyor belt

How is the conveyor belt usually used? The function of the conveyor belt is to move objects from point A to point B with minimal effort. The speed, direction, curvature and size of the conveyor belt vary according to the needs of users. In some industries, conveyor belts transport products back through production or packaging lines.

Conveyor belts are generally divided into two categories: light and heavy.

Lightweight conveyor belt design to meet various material handling requirements of different industries. The working tension of a lightweight belt system is less than 160 pounds per inch of width. The four main types of light conveyor belts are:

- Solid Plastic

- Non-woven fabric

- Thermoplastic overlay

- Lightweight rubber

The top industries that use light belts include:

- Food processing

- Unit package processing

- Pharmaceuticals

- Paper products

Choose heavy-gauge conveyor belts with a tension of at least 160 pounds per inch wide for the most challenging applications. Heavy-duty belt systems are used in applications that require continuous movement of heavy, heavy materials. Belts are usually coated with PTFE to withstand high temperatures.

The top industries that use heavyweight belts include:

- Mining

- Manufacturing

- Waste/Recycling

- High temperature food processing

4. Usage and Applications of conveyor belts

A conveyor belt system affects efficiency, productivity, and labor volumes significantly, regardless of how light or heavy it is. Light and heavy belt systems have different uses and applications across numerous settings and industries.

4.1 Use of conveyor belts

The conveying system has many uses, such as:

- Convey large quantities of materials quickly and reliably

- Stacking materials at the end of the transportation line

- Simplify the process from point A to point B

- Product vertical or horizontal movement, high flexibility

Utilizing conveyor belts has the following advantages:

- Reduce labor, greatly increase productivity and time efficiency

- Prevent workers from being injured by carrying heavy objects

- Please keep the product properly during transportation to avoid damage

- Conveniently transfer products to different routes

- Enjoy relatively simple maintenance, this long-lasting, long-lasting system

4.2 Application on conveyor belt

Conveyor belt systems have applications in many industries, including air travel, mining, manufacturing, pharmaceuticals, and food processing.

At the airport, conveyor belts are the best way to efficiently handle, sort, and load and unload passenger luggage. Luggage conveyor belts are the practical application of industrial conveyor belts. Most people will encounter this situation in their lives-luggage is loaded on the conveyor belt in a safe area, and then quickly transported to the terminal that passengers can reach. The baggage claim area is located on the other side of the loading area where the conveyor belt turns around continuously.

For the pharmaceutical industry, a conveyor belt system transports cartons or palate full of medical supplies for front and back packaging and distribution. In the manufacturing and mining industries, large amounts of materials are transported through tunnels, roads and steep slopes on conveyor belts. Durable belt materials and good use of support rollers are necessary for conveyor belt systems in these industries.

For food processing, products go through a life cycle on a conveyor belt. Items can be rolled, stamped, rolled, glazed, fried, sliced and dusted on the conveyor belt. Imagine how much manpower would be spent on transporting each type of food if you did not do this. Through the conveyor belt, the goods are in large quantities from start to finish, while still maintaining a uniform high quality.

Each industry has its own specifications and requirements, and the type of conveyor belts they use. From shipyards and power plants to bakeries and ice cream factories, conveyor belts are the preferred utility because of its simplicity and reliability.