-

The T2 glue gun adopts the principle of cold vulcanization. When using it, the AB glue strip needs to be filled inside the glue gun. Under the action of the A+B composite adhesive, it can be integrated with the original belt to prevent delamination and shedding. It can completely avoid the occurrence of rework.

The T2 glue gun adopts the principle of cold vulcanization. When using it, the AB glue strip needs to be filled inside the glue gun. Under the action of the A+B composite adhesive, it can be integrated with the original belt to prevent delamination and shedding. It can completely avoid the occurrence of rework. -

We distribute cold adhesive of high quality at a reasonable price, including Germany TRS cold vulcanizing cement, PU adhesive, cleaning solvent, metal premier, etc. It is used for removing the oil and dirt from rubber and metal surface so as to provide a clean and dirt-free environment for intensive bonding.

We distribute cold adhesive of high quality at a reasonable price, including Germany TRS cold vulcanizing cement, PU adhesive, cleaning solvent, metal premier, etc. It is used for removing the oil and dirt from rubber and metal surface so as to provide a clean and dirt-free environment for intensive bonding. -

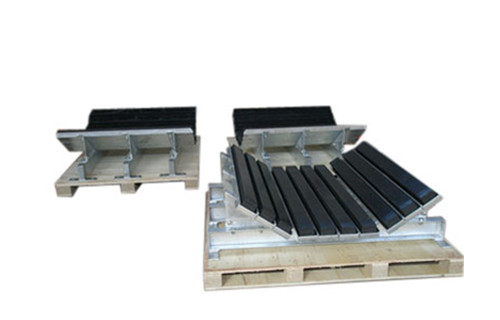

Plain Rubber Pulley Lagging is applied in order to extend the life of the shell by providing a replaceable wearing surface or to improve the friction. It is generally used in Drum, Pulleys, and Bulk Material Handling & Conveying. Plain Rubber Pulley Lagging provided with Bonding Layers for easy installation with cold glues. The plain lagging can be used to eliminate belt spillage, water-shedding, and increase pulleys' service life.

Plain Rubber Pulley Lagging is applied in order to extend the life of the shell by providing a replaceable wearing surface or to improve the friction. It is generally used in Drum, Pulleys, and Bulk Material Handling & Conveying. Plain Rubber Pulley Lagging provided with Bonding Layers for easy installation with cold glues. The plain lagging can be used to eliminate belt spillage, water-shedding, and increase pulleys' service life. -

Belt noodle gum is an uncured black rubber for the belt hot vulcanized splicing, it used as a noodle rubber for steel cord belt splicing or finger splicing of fabric belt. the material can be used to bond to cured inter-core in all standard grade steel cord belts, as well as bond improvement material for fabric belt.

Belt noodle gum is an uncured black rubber for the belt hot vulcanized splicing, it used as a noodle rubber for steel cord belt splicing or finger splicing of fabric belt. the material can be used to bond to cured inter-core in all standard grade steel cord belts, as well as bond improvement material for fabric belt.