-

Rubber Skirt is specially made of polyurethane and soft rubber, the rubber made of high-quality latex, and is resistant to highly abrasive and fine-grained materials. It used on the conveyor loading zone to keep material on the conveyor belt and reduce material spillage and dust. The high wear resistance of polyurethane skirting makes long service life available, usually 3 times longer than rubber skirting board. It is also supplied with/without BL bonding layer, reinforcing fabric layer is also possible.

Rubber Skirt is specially made of polyurethane and soft rubber, the rubber made of high-quality latex, and is resistant to highly abrasive and fine-grained materials. It used on the conveyor loading zone to keep material on the conveyor belt and reduce material spillage and dust. The high wear resistance of polyurethane skirting makes long service life available, usually 3 times longer than rubber skirting board. It is also supplied with/without BL bonding layer, reinforcing fabric layer is also possible. -

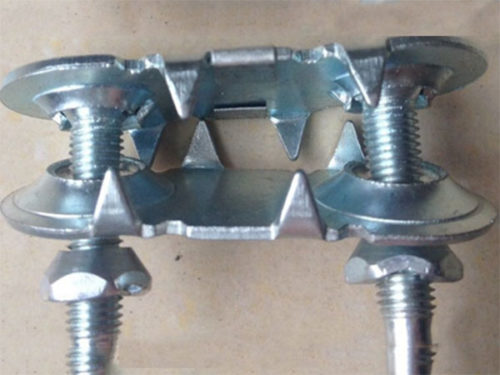

The T2 glue gun adopts the principle of cold vulcanization. When using it, the AB glue strip needs to be filled inside the glue gun. Under the action of the A+B composite adhesive, it can be integrated with the original belt to prevent delamination and shedding. It can completely avoid the occurrence of rework.

The T2 glue gun adopts the principle of cold vulcanization. When using it, the AB glue strip needs to be filled inside the glue gun. Under the action of the A+B composite adhesive, it can be integrated with the original belt to prevent delamination and shedding. It can completely avoid the occurrence of rework. -

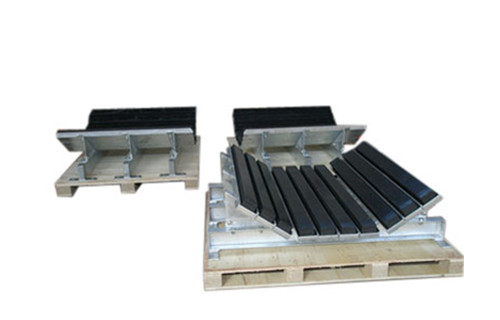

The primary belt cleaner is installed under the center line of the head drum. It is suitable for primary cleaning of materials with large water content, and for one-way operation, cleaning of the conveyor belt of mechanical, cold, or hot vulcanized joints, protecting the belt from damage and prolonging the service life of the belt.

The primary belt cleaner is installed under the center line of the head drum. It is suitable for primary cleaning of materials with large water content, and for one-way operation, cleaning of the conveyor belt of mechanical, cold, or hot vulcanized joints, protecting the belt from damage and prolonging the service life of the belt.