-

Belt noodle gum is an uncured black rubber for the belt hot vulcanized splicing, it used as a noodle rubber for steel cord belt splicing or finger splicing of fabric belt. the material can be used to bond to cured inter-core in all standard grade steel cord belts, as well as bond improvement material for fabric belt.

Belt noodle gum is an uncured black rubber for the belt hot vulcanized splicing, it used as a noodle rubber for steel cord belt splicing or finger splicing of fabric belt. the material can be used to bond to cured inter-core in all standard grade steel cord belts, as well as bond improvement material for fabric belt. -

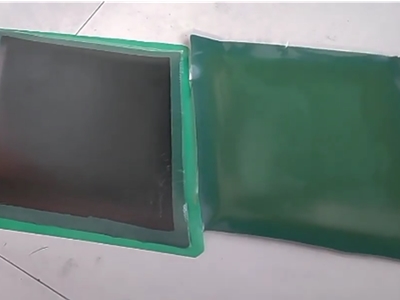

We distribute cold adhesive of high quality at a reasonable price, including Germany TRS cold vulcanizing cement, PU adhesive, cleaning solvent, metal premier, etc. It is used for removing the oil and dirt from rubber and metal surface so as to provide a clean and dirt-free environment for intensive bonding.

We distribute cold adhesive of high quality at a reasonable price, including Germany TRS cold vulcanizing cement, PU adhesive, cleaning solvent, metal premier, etc. It is used for removing the oil and dirt from rubber and metal surface so as to provide a clean and dirt-free environment for intensive bonding. -

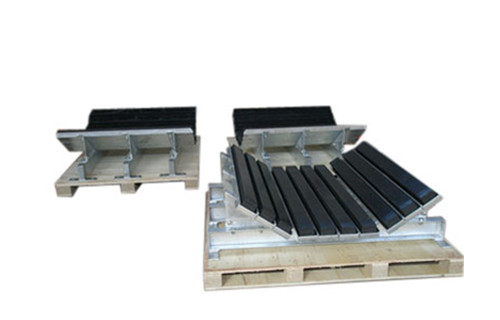

Rubber Skirt is specially made of polyurethane and soft rubber, the rubber made of high-quality latex, and is resistant to highly abrasive and fine-grained materials. It used on the conveyor loading zone to keep material on the conveyor belt and reduce material spillage and dust. The high wear resistance of polyurethane skirting makes long service life available, usually 3 times longer than rubber skirting board. It is also supplied with/without BL bonding layer, reinforcing fabric layer is also possible.

Rubber Skirt is specially made of polyurethane and soft rubber, the rubber made of high-quality latex, and is resistant to highly abrasive and fine-grained materials. It used on the conveyor loading zone to keep material on the conveyor belt and reduce material spillage and dust. The high wear resistance of polyurethane skirting makes long service life available, usually 3 times longer than rubber skirting board. It is also supplied with/without BL bonding layer, reinforcing fabric layer is also possible. -

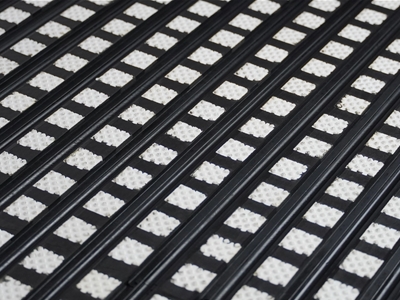

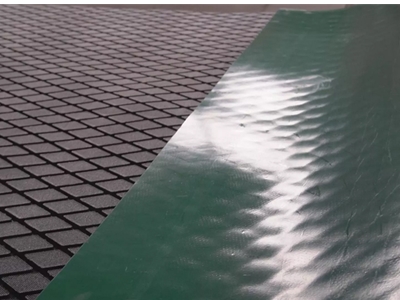

Diamond Rubber Pulley Lagging is designed primarily for use as lagging of conveyor belt pulleys to increase grip and reduce wear and corrosion of the Drive Pulleys shell. Feature:

Diamond Rubber Pulley Lagging is designed primarily for use as lagging of conveyor belt pulleys to increase grip and reduce wear and corrosion of the Drive Pulleys shell. Feature:- Our pulley lagging CN layer doesn’t need to polish before use, it could bond directly

- Reduced Belt Slippage

- Extend Belt and Pulley Service Life

-

Fabric Reinforced Repair Strip(repair band) is made by neoprene based CN bonding layer on one side and NR & SBR etc rubber compound, it reinforced with fabric layer to increase tensile strength. Our Fabric Reinforced Repair Strips produced complying with global standards including DIN, AS(Australia), EN-ISO(Europe), etc.

Fabric Reinforced Repair Strip(repair band) is made by neoprene based CN bonding layer on one side and NR & SBR etc rubber compound, it reinforced with fabric layer to increase tensile strength. Our Fabric Reinforced Repair Strips produced complying with global standards including DIN, AS(Australia), EN-ISO(Europe), etc. -

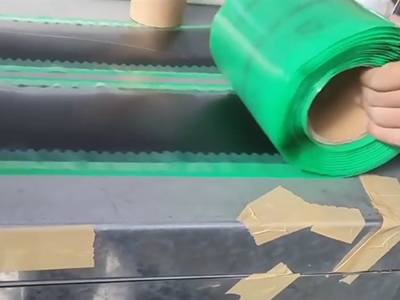

Plain Rubber Pulley Lagging is applied in order to extend the life of the shell by providing a replaceable wearing surface or to improve the friction. It is generally used in Drum, Pulleys, and Bulk Material Handling & Conveying. Plain Rubber Pulley Lagging provided with Bonding Layers for easy installation with cold glues. The plain lagging can be used to eliminate belt spillage, water-shedding, and increase pulleys' service life.

Plain Rubber Pulley Lagging is applied in order to extend the life of the shell by providing a replaceable wearing surface or to improve the friction. It is generally used in Drum, Pulleys, and Bulk Material Handling & Conveying. Plain Rubber Pulley Lagging provided with Bonding Layers for easy installation with cold glues. The plain lagging can be used to eliminate belt spillage, water-shedding, and increase pulleys' service life. -

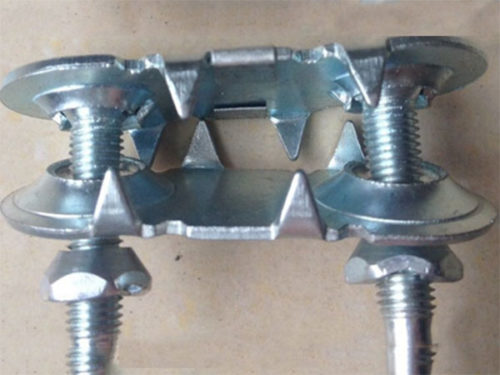

The primary belt cleaner is installed under the center line of the head drum. It is suitable for primary cleaning of materials with large water content, and for one-way operation, cleaning of the conveyor belt of mechanical, cold, or hot vulcanized joints, protecting the belt from damage and prolonging the service life of the belt.

The primary belt cleaner is installed under the center line of the head drum. It is suitable for primary cleaning of materials with large water content, and for one-way operation, cleaning of the conveyor belt of mechanical, cold, or hot vulcanized joints, protecting the belt from damage and prolonging the service life of the belt. -

Reinforced Diamond Repair Patches have an extremely tough cover stock and beveled edges, they are mainly used for maximum puncture resistance. They are used in the event of small or large damages on rubber linings of conveyor belts. Reinforced diamond repair patches especially better used for repairing damages that request higher tensile strength

-

Standard Repair Strip (Repair Rectangular Patch) is made of synthetic rubber compound with a superior quality semi-vulcanized bonding layer on one side. It is a high wear-resistant, and natural rubber strip designed for use to repair damage to conveyor belt covers. As the authentic CN layer(bonding layer), our repair strip doesn’t need to polish before use and the CN layer can be bonded with Rubber directly. Our bonding layer's other characteristic is that its adhesive force increases with time, while the adhesion of the inferior CN layer adhesion doesn’t change over time.

Standard Repair Strip (Repair Rectangular Patch) is made of synthetic rubber compound with a superior quality semi-vulcanized bonding layer on one side. It is a high wear-resistant, and natural rubber strip designed for use to repair damage to conveyor belt covers. As the authentic CN layer(bonding layer), our repair strip doesn’t need to polish before use and the CN layer can be bonded with Rubber directly. Our bonding layer's other characteristic is that its adhesive force increases with time, while the adhesion of the inferior CN layer adhesion doesn’t change over time. -

The T2 glue gun adopts the principle of cold vulcanization. When using it, the AB glue strip needs to be filled inside the glue gun. Under the action of the A+B composite adhesive, it can be integrated with the original belt to prevent delamination and shedding. It can completely avoid the occurrence of rework.

The T2 glue gun adopts the principle of cold vulcanization. When using it, the AB glue strip needs to be filled inside the glue gun. Under the action of the A+B composite adhesive, it can be integrated with the original belt to prevent delamination and shedding. It can completely avoid the occurrence of rework.